Molten metal ceramic filters can remove the non-metallic inclusions in the molten aluminum alloy and treat them with furnace fluxes. Ceramic foam filtration technology has……

Zirconia ceramic foam filter supplier AdTech produces new industrial ceramic products for aluminum melting and casting purification. It has low bulk density (0.25-0.65) g /……

In the process of aluminum melting and casting, bubbles, oxide film and non-metallic inclusions destroy the continuity of metal materials, reduce the effective bearing section……

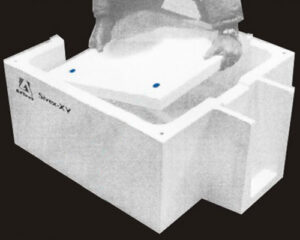

Use of Molten Aluminum Filter: clean the CFF filter box – gently place the foam ceramic filter plate in the filter box – preheat the……

Ceramic Foam Filters Supplier AdTech, not only produces filters, but also produces and sells filter box, online degassing equipment, casting tip and nozzle, refractory plugs,……

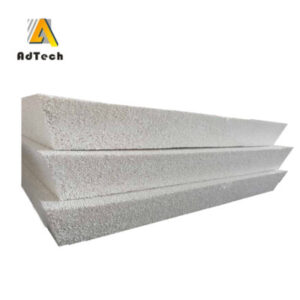

Porous filter material purification mechanism is generally described as diffusion interception and inertial collision interception or through screening, sedimentation and deep bed filtration. AdTech is……

Ceramic filter for foundry has the advantages of high porosity, low loss of thermal shock, high mechanical strength at normal and high temperature, large specific……

Ceramic filter media filtration accuracy is critical to the purity of molten metal. The main factor that affects the filtration accuracy is the maximum pore……

Porous ceramic materials play an important role in cushioning, vibration damping, heat insulation, noise reduction, filtration, etc. High-porosity solids have high rigidity and low density.……

Ceramic foam filter manufacturing process includes the selection of raw materials, produce, drying, and packing. Selection of Raw Materials (1) Foam plastic is the most……