As the demand for high-quality aluminum products increases, especially in the aerospace industry, the need to reduce inclusions in molded products has also increased. A……

During the smelting process of aluminum metal, the molten aluminum will react with water vapor to produce hydrogen and dissolve into the molten aluminum. When……

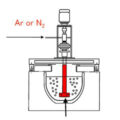

Inert gas such as nitrogen or argon is blown into the online degassing box of aluminum alloy to turn the aluminum liquid over, the impurities……

The aluminum alloy liquid is refined and degassed by a rotary degassing device, and the gas content of the aluminum liquid is required to be……

AdTech three-rotor degassing device is a three-rotor on-line rotating degassing and impurity removal device. Its efficiency and excellence have been affirmed by the majority of……

The online aluminum degassing system achieves better degassing effect with less time and less overall cost. As these growing markets demand higher quality, higher strength,……

Degassing Unit Uses is important for molten aluminum degassing, it is related to the degassing effect and the service life of the degassing unit. Degassing Unit……

The floatation method is usually used for degassing aluminum. AdTech online rotary degassing unit adopts the floatation method to remove hydrogen in molten aluminum. The……

Aluminum Degassing Methods Aluminum Degassing Methods used in the aluminum foundry mainly include the Air Liquide method, Snif method, Alpur method, in-line degassing system, and……

At present, the on-line degassing methods commonly used in aluminum alloy casting process are: SNIF method, ALPUR method, RDU method, MINT method, etc. no matter……