Aluminum casting ceramic filter technical parameters directly affect the efficiency of molten metal filtration and casting speed in the foundry. The technical parameters of Aluminum……

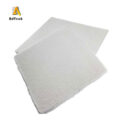

The AdTech foam ceramic filters for aluminium are produced based on a carrier with a solid network structure and organic foam cells. The production steps……

Ceramic Foam Filters are mainly applied for filtration of aluminum and aluminum alloys in foundries and cast houses. With their excellent resistance to attack and……

The requirement for the production of aluminum ingots and billets for the preparation of high-quality aluminum products is that molten aluminum is relatively free of……

According to the molten Al filtration method, the molten Al is passed through a refractory ceramic foam filter to remove inclusions. The larger inclusion particles……

Function of Molten Aluminum Ceramic Foam Filter: Removing impurity and slag: purifying molten aluminum alloy and removing hydrogen at the same time; After filtration, the……

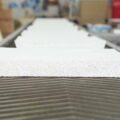

The Molten Metal CFF filtration rating (pore size) ranges from 20 to 80 ppi, but 30ppi.50ppi is the most commonly used. The layout of the……

Ceramic filter filtration efficiency main factors are filtration accuracy and filtration rate. Filtration accuracy refers to the size of the smallest solid particles in the……

Ceramic Foam Filter for Metal is a kind of open-cell mesh with a sponge-like structure and a filter device using ceramic foam as the medium.……

CFF for Foundry is a high quality filter used in molten aluminum, copper based alloys and ferrous metals (including gray alloys, ductile alloys and steel……