Metal Transfer System for Dunkirk Aluminium is equipped with a launder cover to prevent dangerous and expensive leaks. The launder system has a heating system……

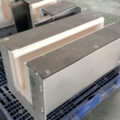

The material of the aluminum transfer launder can be divided into two categories: ceramic fiber and castable. The ceramic fiber launder has the advantages of……

The cover of the launder construction comprises a metal cover, such as a steel jacket; at least one electrical resistor, which is arranged so as……

The molten metal launder is a key component in the large aluminum alloy die casting production line. This is the channel to ensure that the……

The conveying launder part refers to all the mechanisms from the outlet of the holding furnace to the middle part of the pouring system. It……

In most molten metal processes, metal transfer is a critical step because it affects metal quality, productivity, waste volume, and overall safety. The transfer of……

Molten Aluminum Transfer is an important step in aluminum casting. The method of molten aluminum transfer in aluminum alloy smelting production is also a factor……

Launder for Aluminium Casting will be connecting the customer’s existing gas fired aluminum melting furnace to three (3) new electric resistance aluminum holding furnaces located……

Aluminum is guided into the casting machine from the melting furnace through the launder and storage tank. Launders with steel sleeves are lined with refractory……

Insulated Launder is placed in the liquid inlet or liquid outlet of the smelting furnace. Insulated Launder is also called Refractory Troughs, Molten Metal Transfer.……