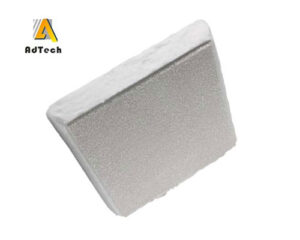

Foam ceramic casting filters have many advantages such as good chemical stability, high specific strength, high temperature resistance, thermal shock resistance, and large specific surface……

Alumina foam ceramic filters can reduce or eliminate casting defects through mechanical interception, rectifying scum and deep adsorption through three filtering and purification mechanisms, and……

In the process of aluminum melting and casting, bubbles, oxide film and non-metallic inclusions destroy the continuity of metal materials, reduce the effective bearing section……

Metal purity is one of the most important requirements in the foundry industry. The best practice in the field of molten metal filtration is to……

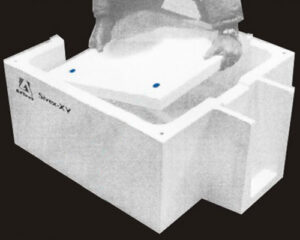

Use of Molten Aluminum Filter: clean the CFF filter box – gently place the foam ceramic filter plate in the filter box – preheat the……

Ceramic Foam Filters Supplier AdTech, not only produces filters, but also produces and sells filter box, online degassing equipment, casting tip and nozzle, refractory plugs,……

Porous filter material purification mechanism is generally described as diffusion interception and inertial collision interception or through screening, sedimentation and deep bed filtration. AdTech is……

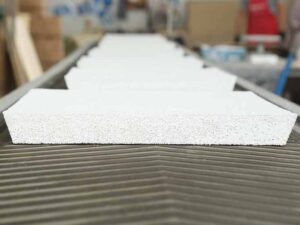

Foam Ceramic Filter Manufacturing Process uses automatic extrusion equipment to make the slurry evenly distributed in the foam skeleton. With the development of science and……

Foundry filters are designed to ensure high purity of blank casting of aluminum alloys at metallurgical plants and for filtering aluminum castings in foundries. Filters……

A porous ceramic filter is a kind of ceramic material made of refractory raw material as aggregate, combined with a binder and other high-temperature sintering.……