Aluminum has been widely used in industrial applications, such as transportation, packaging, automotive, aerospace, electronics. Inclusion content has long been the main quality standard for……

The filtering result of the porous ceramic plate depends on the chemical composition of the inclusions in the melt, the shape of the ceramic foam……

Ceramic filter for aluminum foundry is used for removing entrained solids from molten aluminum alloys before casting. When these inclusions appear in the final cast……

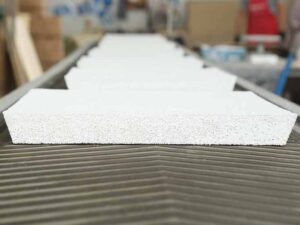

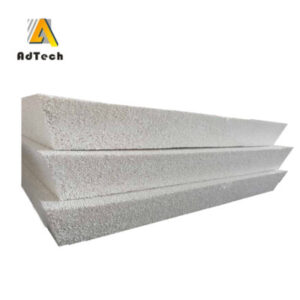

A porous ceramic filter is a kind of ceramic material made of refractory raw material as aggregate, combined with a binder and other high-temperature sintering.……

Ceramic filter media filtration accuracy is critical to the purity of molten metal. The main factor that affects the filtration accuracy is the maximum pore……

Porous ceramic materials play an important role in cushioning, vibration damping, heat insulation, noise reduction, filtration, etc. High-porosity solids have high rigidity and low density.……

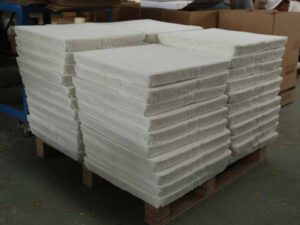

High Grade Ceramic Foam Filters have been used for many years, it can improve the quality of castings and obtain high-quality aluminum die casting parts.……

The ceramic foam filter for aluminum casting can effectively remove large inclusions in the liquid aluminum, and absorb micron-sized fine inclusion particles. Ceramic Foam Filters……

Alumina foam ceramics is an important branch of three types of foam ceramics (alumina, silicon carbide, zirconia), and it is also the earliest type of……

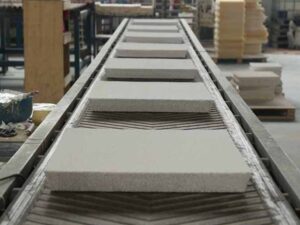

Foundry ceramic filters are made of polyurethane foam plastic and immersed in the ceramic slurry made of ceramic powder, binder, sintering aid, suspending agent, etc.……