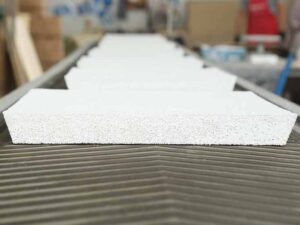

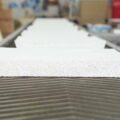

Foam Ceramic Filter Manufacturing Process uses automatic extrusion equipment to make the slurry evenly distributed in the foam skeleton. With the development of science and……

Ceramic Filter Manufacturing Process is important for aluminum liquid filtration. In order to achieve casting of aluminum has good physical and chemical performance and machining……

Foundry filters are designed to ensure high purity of blank casting of aluminum alloys at metallurgical plants and for filtering aluminum castings in foundries. Filters……

Ceramic filter for foundry has the advantages of high porosity, low loss of thermal shock, high mechanical strength at normal and high temperature, large specific……

Silicon Carbide Ceramic Filter has excellent strength and high temperature impact resistance and chemical corrosion. It can withstand high temperatures up to about 1560 °C.……

Ceramic filter for aluminum foundry is used for removing entrained solids from molten aluminum alloys before casting. When these inclusions appear in the final cast……

A porous ceramic filter is a kind of ceramic material made of refractory raw material as aggregate, combined with a binder and other high-temperature sintering.……

Ceramic filter media filtration accuracy is critical to the purity of molten metal. The main factor that affects the filtration accuracy is the maximum pore……

Ceramic foam filter manufacturing process includes the selection of raw materials, produce, drying, and packing. Selection of Raw Materials (1) Foam plastic is the most……

High Grade Ceramic Foam Filters have been used for many years, it can improve the quality of castings and obtain high-quality aluminum die casting parts.……