Foam ceramic casting filters have many advantages such as good chemical stability, high specific strength, high temperature resistance, thermal shock resistance, and large specific surface……

Foam Ceramics filter uses polyurethane foam as the carrier. After hydrolysis, the foam is immersed in the coating made of ceramic powder, binder, sintering aid,……

Alumina foam ceramic filters can reduce or eliminate casting defects through mechanical interception, rectifying scum and deep adsorption through three filtering and purification mechanisms, and……

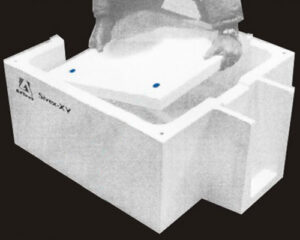

Ceramic disc filter needs to use properly, otherwise, the effect is worse than other filters. The area of metal passing through the filter should be……

Ceramic Foam Filter Suppliers offer the purification method, so that the aluminum melt can pass through the ceramic foam filter, it can separate the solid……

In the process of aluminum melting and casting, bubbles, oxide film and non-metallic inclusions destroy the continuity of metal materials, reduce the effective bearing section……

Metal purity is one of the most important requirements in the foundry industry. The best practice in the field of molten metal filtration is to……

Foam Furnace Filters are used to filter molten aluminum in the foundry. Our ceramic foam filters have a 3D mesh structure, high porosity, and low……

Alumina ceramic foam filters can effectively remove solid state mixed with molten metal, so aluminum alloy can be successfully forged, aluminum foil is manufactured, and……

Ceramic Filters For Foundry are used for cast aluminum ingots and aluminum rods. Ceramic filters have been widely used at home and abroad, they save……