Foam ceramic casting filters have many advantages such as good chemical stability, high specific strength, high temperature resistance, thermal shock resistance, and large specific surface……

Molten aluminum filtration method is mainly to let the aluminum melt pass through the ceramic filter to separate the solid inclusions suspended in the melt.……

Alumina foam ceramic filters can reduce or eliminate casting defects through mechanical interception, rectifying scum and deep adsorption through three filtering and purification mechanisms, and……

In the process of aluminum melting and casting, bubbles, oxide film and non-metallic inclusions destroy the continuity of metal materials, reduce the effective bearing section……

Metal purity is one of the most important requirements in the foundry industry. The best practice in the field of molten metal filtration is to……

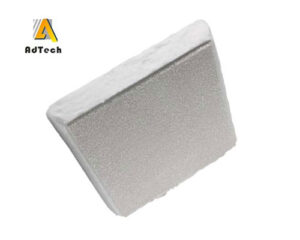

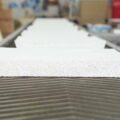

Foam Furnace Filters are used to filter molten aluminum in the foundry. Our ceramic foam filters have a 3D mesh structure, high porosity, and low……

In order to be used for various levels of heat dissipation during casting, ceramic casting filters must be more robust. The best quality materials are……

Ceramic foam filter is a three-dimensional grid structure of porous ceramics with high porosity (80% to 90%). Because it has the advantages of low density,……

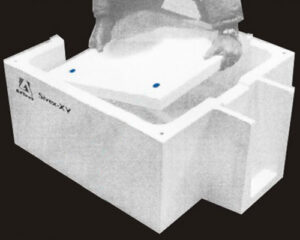

Ceramic Foam Filters Supplier AdTech, not only produces filters, but also produces and sells filter box, online degassing equipment, casting tip and nozzle, refractory plugs,……

Porous filter material purification mechanism is generally described as diffusion interception and inertial collision interception or through screening, sedimentation and deep bed filtration. AdTech is……