Foam Ceramic Filter Manufacturing Process uses automatic extrusion equipment to make the slurry evenly distributed in the foam skeleton. With the development of science and……

Ceramic Filter Manufacturing Process is important for aluminum liquid filtration. In order to achieve casting of aluminum has good physical and chemical performance and machining……

Foam Furnace Filter plays an important role in filtering inclusions in molten metal. The casting defects of slag greatly affect the production efficiency and economic……

In casting production, casting defects caused by non-metallic inclusions account for 50% to 60% of the total number of waste products. Inclusion defects not only……

Foundry filters are designed to ensure high purity of blank casting of aluminum alloys at metallurgical plants and for filtering aluminum castings in foundries. Filters……

Ceramic Foundry Filter removes inclusions in aluminum alloy melt. Inclusions and gases in the metal have a significant impact on the strength, corrosion resistance, and……

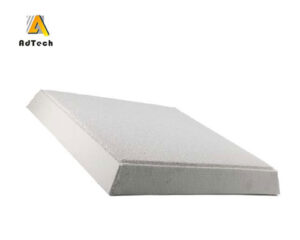

Ceramic filter for foundry has the advantages of high porosity, low loss of thermal shock, high mechanical strength at normal and high temperature, large specific……

Ceramic foam filter supplier AdTech offers CFF, filtering effect is better, it is suitable for filtering the inclusions in molten aluminum. It has the following……

Ceramic Foam Filters Manufacturing Process includes adding pore former process, foaming process, Sol-Gel process, solid particle sintering process, particle accumulation process, Gel injection molding process,……

Foundry ceramic filter plate is an energy-saving and environmentally friendly product, which is widely used in the dehydration process of metal ore operations such as……