The launder system for aluminum casting is divided into a direct flow trough, an inclined launder, a distribution launder, a corner launder, and a lifting……

In conventional casting systems, a metal launder typically has a plurality of metal discharge spouts, and spans a like number of casting stations. It is……

The cover of the launder construction comprises a metal cover, such as a steel jacket; at least one electrical resistor, which is arranged so as……

The refractory lining of the aluminum silicate ceramic trough and launder is a separate element, which can be detached as an integral part and replaced……

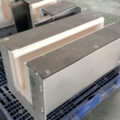

The aluminum casting launder is composed of a solid low-carbon steel shell, lined with refractory material. In addition to low thermal conductivity and high thermal……

The molten aluminum launder system produced by AdTech is used between the on-line degassing filter equipment and the continuous casting mill. It has dual functions:……

The molten metal launder is a key component in the large aluminum alloy die casting production line. This is the channel to ensure that the……

The conveying launder part refers to all the mechanisms from the outlet of the holding furnace to the middle part of the pouring system. It……

In most molten metal processes, metal transfer is a critical step because it affects metal quality, productivity, waste volume, and overall safety. The transfer of……

Molten Aluminum Transfer is an important step in aluminum casting. The method of molten aluminum transfer in aluminum alloy smelting production is also a factor……