Ceramic foam filter uses is important for molten aluminum filtering. In addition to the actual production requirements of aluminum product quality, we should also consider……

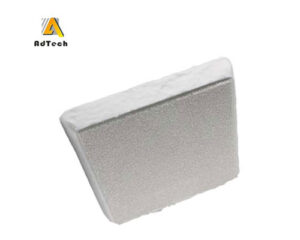

Foam ceramic filters manufacturer AdTech can provide 20-80 PPI ceramic foam filter. The ceramic foam filter is made of continuous mesh foam plastics, immersed in……

Foam filter manufacturing process is made of reticulated polyurethane foam plastic as the carrier, and the foam plastic is uniformly saturated to soak the ceramic……

Metal purity is one of the most important requirements in the foundry industry. The best practice in the field of molten metal filtration is to……

Ceramic foam filter is a three-dimensional grid structure of porous ceramics with high porosity (80% to 90%). Because it has the advantages of low density,……

Ceramic filter for foundry has the advantages of high porosity, low loss of thermal shock, high mechanical strength at normal and high temperature, large specific……

Ceramic foam filter supplier AdTech offers CFF, filtering effect is better, it is suitable for filtering the inclusions in molten aluminum. It has the following……

Ceramic Foam Filters Manufacturing Process includes adding pore former process, foaming process, Sol-Gel process, solid particle sintering process, particle accumulation process, Gel injection molding process,……

With the development of the metallurgical industry, aluminum foundries pay more and more attention to the purity of aluminum. The CFF filtering method is currently……

Ceramic foam filter manufacturing process includes the selection of raw materials, produce, drying, and packing. Selection of Raw Materials (1) Foam plastic is the most……