The material of the aluminum transfer launder can be divided into two categories: ceramic fiber and castable. The ceramic fiber launder has the advantages of……

The launder system for aluminum casting is divided into a direct flow trough, an inclined launder, a distribution launder, a corner launder, and a lifting……

In conventional casting systems, a metal launder typically has a plurality of metal discharge spouts, and spans a like number of casting stations. It is……

The ceramic launder system provides considerable advantages. It decreases the need for embedding materials and the maintenance intervals of the launders that are used in……

The refractory lining of the aluminum silicate ceramic trough and launder is a separate element, which can be detached as an integral part and replaced……

AdTech supplies a launder for the conveyance of molten metal. The metal flows in the lower part of the launder construction in a channel defined……

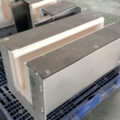

The aluminum casting launder is composed of a solid low-carbon steel shell, lined with refractory material. In addition to low thermal conductivity and high thermal……

When processing liquid aluminum alloys, the melt is usually allowed to settle before casting to precipitate solid inclusion particles. These particles, especially oxides, borides, and……

The conveying launder part refers to all the mechanisms from the outlet of the holding furnace to the middle part of the pouring system. It……

Refractory Casting Launder is one of the Refractories primary product offerings from our fabrication department. Our high-quality refractory casting launder has been provided to both……