Aluminum degassing equipment can remove impurities and alkali metals in molten aluminum, thereby improving metal quality. Inclusions may result in decreased fluidity, increased porosity, decreased……

The hydrogen content in the aluminum melt has a decisive influence on the properties of aluminum and aluminum alloys. Therefore, hydrogen degassing has become one……

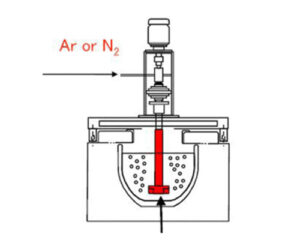

Rotary Degassing With Nitrogen was first applied to continuous refining in large melting furnaces. The inert gas is passed into the liquid through a specially……

There are many factors that affect the quality of aluminum and its alloys. Among them, the hydrogen content, inclusions and alkali metal concentration of molten……

Degassing aluminum with nitrogen is an economical degassing method. In aluminum foundry, it is a common practice to degass molten aluminum with argon gas. It……

Degassing Molten Aluminum is one of the most effective purification methods for aluminum. With the increasing demand for non-ferrous metal castings (especially aluminum and aluminum……

The rotating degassing box impeller works by increasing the surface area of the inert gas introduced into the metal. The smaller nitrogen bubbles produced by……

Inert gas refining is to continuously blow inert bubbles into the melt, and bring the oxidized inclusions and hydrogen out of the liquid surface while……

Hydrogen degassing from melt can improve the quality of aluminum. In Adtech, metal processing includes flux injection and rotary degassing. Hydrogen is an impurity, and……

How To Degas Aluminum? The degassing treatment of the melt causes the injector immersed in the melt to rotate so that the scavenging gas (usually……