Use of Molten Aluminum Filter: clean the CFF filter box – gently place the foam ceramic filter plate in the filter box – preheat the……

Practice has proved that the foam ceramic filter plate is an economical way to remove aluminum inclusions. Due to the different conditions of use, the……

Foam Ceramic Filter Manufacturing Process uses automatic extrusion equipment to make the slurry evenly distributed in the foam skeleton. With the development of science and……

Foam filter material is a modern material in demand in many industrial fields. It is made from highly dispersed mineral powders, as well as from……

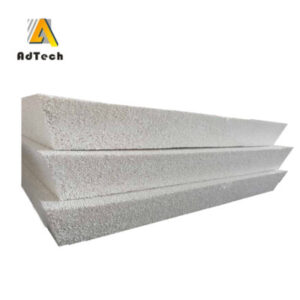

Ceramic filter for foundry has the advantages of high porosity, low loss of thermal shock, high mechanical strength at normal and high temperature, large specific……

Ceramic foam filter supplier AdTech offers CFF, filtering effect is better, it is suitable for filtering the inclusions in molten aluminum. It has the following……

Ceramic Foam Filters Manufacturing Process includes adding pore former process, foaming process, Sol-Gel process, solid particle sintering process, particle accumulation process, Gel injection molding process,……

Porous ceramic materials play an important role in cushioning, vibration damping, heat insulation, noise reduction, filtration, etc. High-porosity solids have high rigidity and low density.……

Ceramic foam filter manufacturing process includes the selection of raw materials, produce, drying, and packing. Selection of Raw Materials (1) Foam plastic is the most……

The ceramic foam filter can improve the cleanliness of the melton aluminum. AdTech alumina ceramic foam filter can effectively eliminate large inclusions in the molten aluminum,……