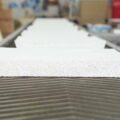

Foam filter manufacturing process is made of reticulated polyurethane foam plastic as the carrier, and the foam plastic is uniformly saturated to soak the ceramic……

Ceramic foam filter manufacturer process include foam impregnation, drying, and sintering. Ceramic Foam Filter Manufacturer Process Impregnation The traditional domestic impregnation method is manual extrusion,……

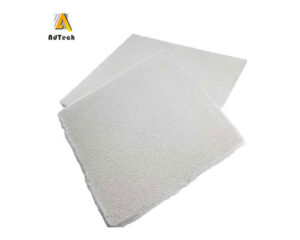

Foam Ceramics filter uses polyurethane foam as the carrier. After hydrolysis, the foam is immersed in the coating made of ceramic powder, binder, sintering aid,……

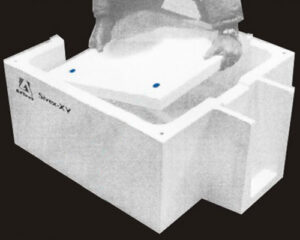

Ceramic disc filter needs to use properly, otherwise, the effect is worse than other filters. The area of metal passing through the filter should be……

In the process of aluminum melting and casting, bubbles, oxide film and non-metallic inclusions destroy the continuity of metal materials, reduce the effective bearing section……

Foam Furnace Filters are used to filter molten aluminum in the foundry. Our ceramic foam filters have a 3D mesh structure, high porosity, and low……

Porous Ceramic Filters are phosphate-free high alumina-based products with high porosity and mechanochemical stability. They have excellent resistance to molten aluminum thermal erosion and corrosion.……

Alumina ceramic foam filters can effectively remove solid state mixed with molten metal, so aluminum alloy can be successfully forged, aluminum foil is manufactured, and……

Ceramic Filters For Foundry are used for cast aluminum ingots and aluminum rods. Ceramic filters have been widely used at home and abroad, they save……

Use of Molten Aluminum Filter: clean the CFF filter box – gently place the foam ceramic filter plate in the filter box – preheat the……