Ceramic Foam Filter from AdTech Metallurgical Materials Co., Ltd has been focusing on research, development, production and marketing of the adhesive ceramic foam filter(CFF) for……

The porous ceramic filters have a three-dimensionally interconnected open-pore (ceramic foam) network-like pore structure, etc., in which the ceramic form is preferably used as a……

Function of Molten Aluminum Ceramic Foam Filter: Removing impurity and slag: purifying molten aluminum alloy and removing hydrogen at the same time; After filtration, the……

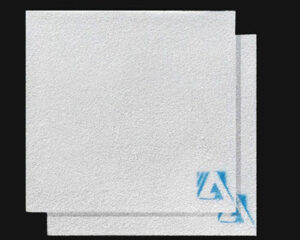

The Molten Metal CFF filtration rating (pore size) ranges from 20 to 80 ppi, but 30ppi.50ppi is the most commonly used. The layout of the……

Ceramic casting filters can improve the quality of finished products (foil, block, ingot, bar, profile, etc.) and meet the requirements of high purity cast metal.……

Molten metal foam filters can reduce casting defects. Metal foam filters are characterized by light weight, high mechanical strength, large surface area and high porosity.……

Foam filter manufacturing process is made of reticulated polyurethane foam plastic as the carrier, and the foam plastic is uniformly saturated to soak the ceramic……

Ceramic foam filter manufacturer process include foam impregnation, drying, and sintering. Ceramic Foam Filter Manufacturer Process Impregnation The traditional domestic impregnation method is manual extrusion,……

Ceramic foam filter is a three-dimensional grid structure of porous ceramics with high porosity (80% to 90%). Because it has the advantages of low density,……

Practice has proved that the foam ceramic filter plate is an economical way to remove aluminum inclusions. Due to the different conditions of use, the……