The demand for aluminum products such as aluminum canned drinks and aluminum foil for packaging purposes has increased in recent years. If there are solid……

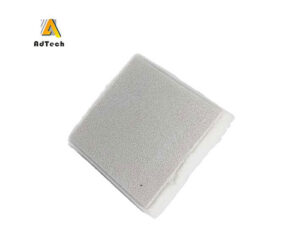

Molten metal foam ceramic filter has an open-cell structure and a plurality of interconnected voids surrounded by ceramic fiber mesh. The porous structure of the……

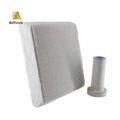

Function of Molten Aluminum Ceramic Foam Filter: Removing impurity and slag: purifying molten aluminum alloy and removing hydrogen at the same time; After filtration, the……

Ceramic filter plates are very important to the quality of aluminum melt, which greatly affects the subsequent processing performance and the quality of the final……

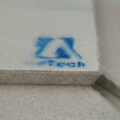

Ceramic foam material is a new type of inorganic non-metallic filter material, ceramic foam material mainly uses raw ore powder, kaolin, or ceramic industrial waste……

Ceramic casting filters can improve the quality of finished products (foil, block, ingot, bar, profile, etc.) and meet the requirements of high purity cast metal.……

Molten metal foam filters can reduce casting defects. Metal foam filters are characterized by light weight, high mechanical strength, large surface area and high porosity.……

Foam filter manufacturing process is made of reticulated polyurethane foam plastic as the carrier, and the foam plastic is uniformly saturated to soak the ceramic……

Ceramic foam filter manufacturer process include foam impregnation, drying, and sintering. Ceramic Foam Filter Manufacturer Process Impregnation The traditional domestic impregnation method is manual extrusion,……

Molten aluminum filtration method is mainly to let the aluminum melt pass through the ceramic filter to separate the solid inclusions suspended in the melt.……