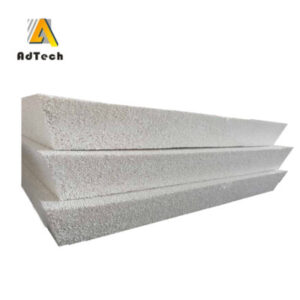

Foam filter manufacturing process is made of reticulated polyurethane foam plastic as the carrier, and the foam plastic is uniformly saturated to soak the ceramic……

Ceramic foam filter manufacturer process include foam impregnation, drying, and sintering. Ceramic Foam Filter Manufacturer Process Impregnation The traditional domestic impregnation method is manual extrusion,……

In the process of aluminum melting and casting, bubbles, oxide film and non-metallic inclusions destroy the continuity of metal materials, reduce the effective bearing section……

Metal purity is one of the most important requirements in the foundry industry. The best practice in the field of molten metal filtration is to……

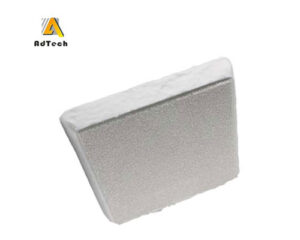

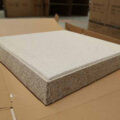

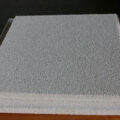

Ceramic foam filter is a three-dimensional grid structure of porous ceramics with high porosity (80% to 90%). Because it has the advantages of low density,……

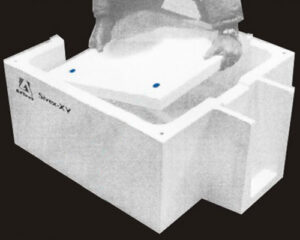

Use of Molten Aluminum Filter: clean the CFF filter box – gently place the foam ceramic filter plate in the filter box – preheat the……

Practice has proved that the foam ceramic filter plate is an economical way to remove aluminum inclusions. Due to the different conditions of use, the……

Foam filter material is a modern material in demand in many industrial fields. It is made from highly dispersed mineral powders, as well as from……

Ceramic filter for foundry has the advantages of high porosity, low loss of thermal shock, high mechanical strength at normal and high temperature, large specific……

Porous ceramic materials play an important role in cushioning, vibration damping, heat insulation, noise reduction, filtration, etc. High-porosity solids have high rigidity and low density.……