There are many and molten aluminum filtration methods for removing solid particulate impurities before introducing metal into the mold. There are the following molten aluminum……

The aluminium casting ceramic filter plate provides an effective and effective method to remove aluminum inclusions. The actual removal effect will vary according to the……

Alumina ceramic foam filter board can effectively remove and absorb large or small impurities in molten aluminum, improve the surface quality, product performance, and microstructure……

The demand for aluminum products such as aluminum canned drinks and aluminum foil for packaging purposes has increased in recent years. If there are solid……

In aluminum casting production, the casting rejection rate due to casting defects such as non-metallic inclusions generally reaches 50% 60% of the total number of……

Ceramic filter plates are very important to the quality of aluminum melt, which greatly affects the subsequent processing performance and the quality of the final……

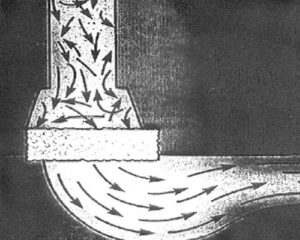

Molten aluminum foam filter can not only effectively remove a large number of heterogeneous impurities in molten aluminum, but also filter out a few microns……

Molten metal foam filters can reduce casting defects. Metal foam filters are characterized by light weight, high mechanical strength, large surface area and high porosity.……

Foam filter manufacturing process is made of reticulated polyurethane foam plastic as the carrier, and the foam plastic is uniformly saturated to soak the ceramic……

Ceramic foam filter manufacturer process include foam impregnation, drying, and sintering. Ceramic Foam Filter Manufacturer Process Impregnation The traditional domestic impregnation method is manual extrusion,……