The usage of Ceramic Foam Filters (CFFs) for aluminium alloy grew continuously in the metal casting process, for the reason that the value-added is greater……

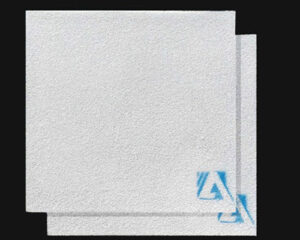

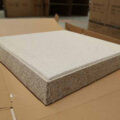

The ceramic foam filter for molten Al includes a refractory aggregate mesh member coated with a compound that can soften or stick at the temperature……

In order to ensure that the downstream processed ingots or billets meet the strict requirements of high-quality products, such as rigid and flexible packaging materials,……

After degassing the molten aluminum, all remaining solids or impurities (such as oxides) must be removed by filtration. Foundries usually use ceramic foam molten metal……

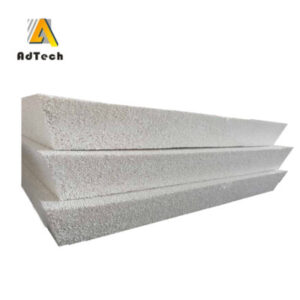

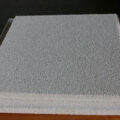

CFF can achieve high aluminum filtration efficiency. The bridge-like structure of inclusions in the top area of the filter helps to improve efficiency. As we……

Molten aluminium foam ceramic filter has ceramic foam in the form of a honeycomb structure, and the ceramic foam filter is generally used to filter……

In aluminum casting production, the casting rejection rate due to casting defects such as non-metallic inclusions generally reaches 50% 60% of the total number of……

Molten metal ceramic filters can remove the non-metallic inclusions in the molten aluminum alloy and treat them with furnace fluxes. Ceramic foam filtration technology has……

In the process of aluminum melting and casting, bubbles, oxide film and non-metallic inclusions destroy the continuity of metal materials, reduce the effective bearing section……

Porous ceramic materials play an important role in cushioning, vibration damping, heat insulation, noise reduction, filtration, etc. High-porosity solids have high rigidity and low density.……