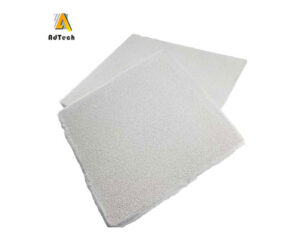

Molten metal foam filters can reduce casting defects. Metal foam filters are characterized by light weight, high mechanical strength, large surface area and high porosity.……

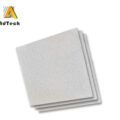

Foam filter manufacturing process is made of reticulated polyurethane foam plastic as the carrier, and the foam plastic is uniformly saturated to soak the ceramic……

Ceramic foam filter manufacturer process include foam impregnation, drying, and sintering. Ceramic Foam Filter Manufacturer Process Impregnation The traditional domestic impregnation method is manual extrusion,……

In order to be used for various levels of heat dissipation during casting, ceramic casting filters must be more robust. The best quality materials are……

Use of Molten Aluminum Filter: clean the CFF filter box – gently place the foam ceramic filter plate in the filter box – preheat the……

Function of Molten Metal Ceramic Foam Filter • Removal of impurities and slag: purification of molten metal and simultaneous degassing (adjustment of turbulence): -After filtering,……

Practice has proved that the foam ceramic filter plate is an economical way to remove aluminum inclusions. Due to the different conditions of use, the……

Foam filter material is a modern material in demand in many industrial fields. It is made from highly dispersed mineral powders, as well as from……