The degassing device mainly treats molten metal containing a certain amount of hydrogen and other residues (alkali metals, slag inclusions) to improve the cleanliness of……

AdTech degassing equipment has an ultra-long life furnace body using a new high-silicon molten material manufacturing technology. The degassing rotor, heater protection sleeve, and thermocouple……

During the smelting process of aluminum metal, the molten aluminum will react with water vapor to produce hydrogen and dissolve into the molten aluminum. When……

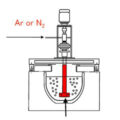

Inert gas such as nitrogen or argon is blown into the online degassing box of aluminum alloy to turn the aluminum liquid over, the impurities……

As the first process of aluminum processing, if the billet has “innate defects” (such as inclusions, pores, etc.) caused by the casting, no matter what……

The online aluminum degassing system achieves better degassing effect with less time and less overall cost. As these growing markets demand higher quality, higher strength,……

When the aluminum liquid enters the inlet of the degassing device, in order to prevent the air from entering the hydrogen removal device from the……

The floatation method is usually used for degassing aluminum. AdTech online rotary degassing unit adopts the floatation method to remove hydrogen in molten aluminum. The……

At present, the on-line degassing methods commonly used in aluminum alloy casting process are: SNIF method, ALPUR method, RDU method, MINT method, etc. no matter……

Metal degassing is a technical intermediate step in aluminum production between the melting and casting of metals. Due to the reaction with water vapor, hydrogen……