As the demand for high-quality aluminum products increases, especially in the aerospace industry, the need to reduce inclusions in molded products has also increased. A……

Online degassing equipments can improve metal quality, reduce melt loss from dross and optimize cast parts. Online degassing helps remove hydrogen, inclusions and alkali metals……

The aluminum alloy liquid is refined and degassed by a rotary degassing device, and the gas content of the aluminum liquid is required to be……

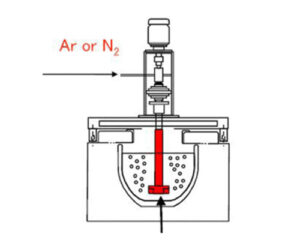

AdTech three-rotor degassing device is a three-rotor on-line rotating degassing and impurity removal device. Its efficiency and excellence have been affirmed by the majority of……

At present, the on-line degassing methods commonly used in aluminum alloy casting process are: SNIF method, ALPUR method, RDU method, MINT method, etc. no matter……

Degassing equipment is located on the line between the furnace and the casting station, and its role is to remove impurities contained in the molten……

Degassing aluminum with nitrogen is an economical degassing method. In aluminum foundry, it is a common practice to degass molten aluminum with argon gas. It……

Rotary degassing is one of the most effective degassing methods by using inert gas (nitrogen). Reducing hydrogen content in molten aluminum before casting is one……

Molten Metal Cleanliness is one of the major challenges for most foundries. They have to produce slabs that contain enough hydrogen, alkali metals (mainly sodium)……

Online refining equipment outside the furnace is an advanced melt purification method, compared with the refining process in the furnace. The purification effect is good……