Ceramic filter for foundry has the advantages of high porosity, low loss of thermal shock, high mechanical strength at normal and high temperature, large specific……

Ceramic fiber filtration technology is one of the faster-developing filtration technologies in recent years. Compared with the traditional granular filter material, the specific surface area……

Ceramics are rarely completely dense, because in most cases, holes cannot be completely avoided. In fact, the existence of pores is one of the main……

Honeycomb ceramic filter has natural chemical adsorption (affinity) ability to oxides, and absorbs impurities (including particles smaller than the pore size) in the molten metal……

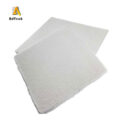

Ceramic foam filter manufacturer AdTech develops and produces the CFF for aluminum. It is widely used in aluminum foundry. With the development of science and……

Ceramic filter for aluminum foundry is used for removing entrained solids from molten aluminum alloys before casting. When these inclusions appear in the final cast……

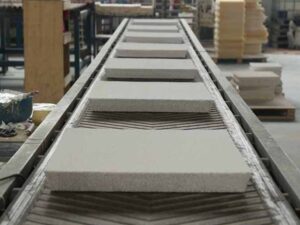

Ceramic foam filter manufacturing process includes the selection of raw materials, produce, drying, and packing. Selection of Raw Materials (1) Foam plastic is the most……

Alumina foam ceramic filter plates are very important in improving the quality of smelted aluminum alloy melts, which greatly affect the subsequent processing performance and……

Alumina foam ceramics is an important branch of three types of foam ceramics (alumina, silicon carbide, zirconia), and it is also the earliest type of……

Foundry ceramic filters are made of polyurethane foam plastic and immersed in the ceramic slurry made of ceramic powder, binder, sintering aid, suspending agent, etc.……