Al Alloy Granulated Flux is mainly used to remove hydrogen and scum in aluminum water, as well as high-temperature melt purification (refining) treatment of aluminum alloy. Its basic function is to remove internal inclusions and hydrogen in high-temperature melt. This makes the molten aluminum more pure and also has the effect of removing slag.

Some members of the aluminum concentrate are easily decomposed at high temperatures, and the generated gas can react with hydrogen, and can strongly adsorb the slag and quickly escape from the melt, thereby playing a role in removing the slag.

Al Alloy Granulated Flux can be used in a variety of aluminum alloy melts, and can be used for pure aluminum smelting, refining and slagging. When using, just sprinkle the Al Alloy Refine Flux on the surface, then quickly dissolve it in the aluminum liquid, and then fully stir it. If a jet is used, it is best to use an inert gas to inject the refined agent, for example, nitrogen and argon can be selected.

For the production of certain alloys, nitrogen blowing is required for refining (about 30 minutes) to drive large fluctuations in liquid aluminum, so it is best to adjust the nitrogen pressure and control the blowing height at 10-15mm.

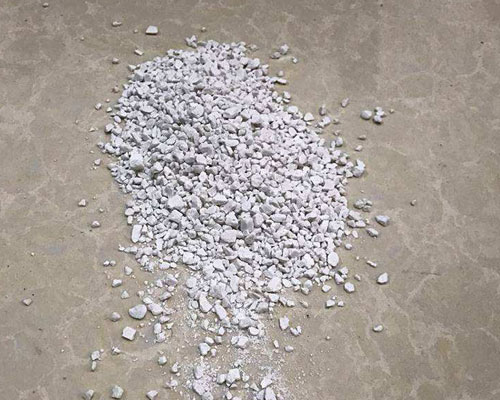

Al Alloy Granulated Flux

AdTech refining agent adopts the principle of combining liquid metal compounds to develop and configure products to reduce smoke, reduce burn damage, and be environmentally friendly and economical.

AdTech refining agent solves the traditional refining effect caused by large amount and high aluminum ash content. AdTech’s refining agent uses 1.5-2.0kg per ton of aluminum and discharges 0.8-1% of aluminum ash, and meets the requirements of high-precision aluminum alloy casting. , Effectively increase the rate of return of molten metal by 0.6-0.8%, and achieve the purpose of energy saving and consumption reduction.

AdTech refining agent is properly heated and sieved, with uniform particle size, which is beneficial for the refining tank to evenly enter the lower layer of the aluminum liquid under the action of the carrier gas (N 2 or Ar ), which fully solves the traditional pipe blockage and failure Dispersion is not conducive to ensuring casting quality and other issues.