In the production process of aluminum alloys, it is often necessary to add various alloying elements such as manganese, iron, silicon, magnesium, and copper. The addition of these alloy elements is mainly carried out through intermediate alloys or alloy element additives. The so-called alloy element additive is a block formed by mixing alloy element powder and other fluxes.

Since the advent of alloying element additives, it has been strongly welcomed by the casting industry. This additive is easy to use and can be easily put into the melting furnace without special equipment. The additive block has a relatively large specific gravity. After being put into the metal solution, it naturally sinks to prevent the powder from floating on the surface of the melt. Alloy additives have a high content of alloy elements, which can save a lot of storage and transportation expenses, so alloy additives have a higher cost advantage. The alloy element additive is composed of metal powder, flux and binder. The content of metal powder is generally 70% to 85%, the content of flux is 15% to 30%, and only a small amount of binder is needed, 0.5-2.0%. The processing process is to uniformly mix the powder of each component, and then press it into a cake shape under high pressure. The size of the block can vary from 50 grams to 2000 grams.

The flux is mainly a fluorine salt (such as potassium fluoroaluminate) or a mixture of a fluorine salt and a chlorine salt (such as KCl). The mixture of potassium fluoroaluminate and KCl is a commonly used fluxing agent, and some heating agents are added. Although the additive composed of alloy element powder and flux has a good melting speed, these salt fluxes are not necessary additives in the alloying process, and are eventually turned into waste slags, which increases the alloying cost. Salt fluxes tend to absorb moisture, and are also prone to mixing with various impurities. Therefore, the addition of additives containing flux has the risk of bringing impurities into the melt and increasing the gas content of the melt. Increasing the amount of slag removal, consuming energy, and increasing management costs such as storage and transportation. Fluoride salt flux produces a lot of smoke when it melts, affecting the environment and the health of the operating workers.

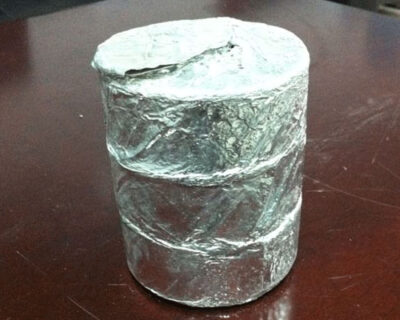

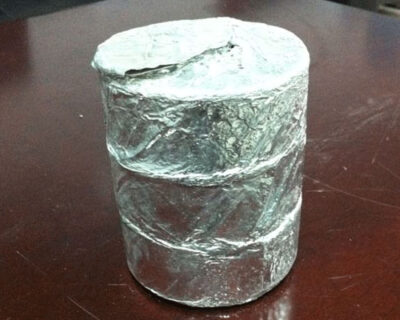

Alloy Element Additive

In the smelting process of aluminum and its alloys, melt quality and environmental issues are important issues in the aluminum industry. These are closely related to the melt processing technology and the materials used. Aluminum ingots often inevitably contain higher alkali metal impurities such as sodium, calcium and lithium. Non-metallic impurities, organic materials and water vapor are usually mixed with the returned materials and aluminum scrap inside the factory. These alkali metals, non-metallic slag inclusions and water vapor will cause serious quality problems for the casting and subsequent processing of aluminum and its alloys. Therefore, before pouring, the refining agent must be used to refining the aluminum liquid.

AdTech provides an alloy element additive for the production of aluminum alloys. The alloy elements added can be quickly melted and fully absorbed by the melt. At the same time, it has excellent refining functions and achieves the effect of refining aluminum melt.