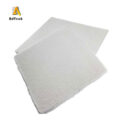

Alu Asian Foundry Filters used in Norway Aluminium has the following main characteristics: high mechanical strength, high temperature resistance, no slag, high temperature impact resistance, and prevention of side leakage of molten aluminum.

Advantages of Alu Asian Foundry Filters

1. By adopting the principle of adsorption, large inclusions in molten aluminum can be effectively removed, and small inclusions of small size can be effectively adsorbed

2. No slag is dropped, effectively reducing the pollution of molten aluminum

3. Improved good thermal shock resistance and resistance to molten metal corrosion

4. Automatic assembly line production, three calibration procedures, correct size, more in line with the filter box

5. Improve surface quality, improve product performance, and improve microstructure.

Norway Aluminium feels that inclusions will be generated to varying degrees during the melting of aluminum alloys. A ceramic foam filter is required.

Their existence will destroy the continuity of the aluminum alloy matrix, reduce the plasticity, toughness and corrosion resistance, and reduce the process performance and surface quality of the aluminum alloy.

The most common hydrogen and oxide inclusions in aluminum alloy melts.

Most of the most common oxide slag inclusions in aluminum alloy casting production are caused by the mixing of air or water vapor in the aluminum melt.

Therefore, the degassing refining of aluminum melt is particularly important, and the degassing effect of furnace side blowing refining is the best.

Norway Aluminium believes that 5182 aluminum alloy has good corrosion resistance, processing performance and welding performance, and is widely used in the processing of can lids, automobile body panels, control panels, reinforcements and brackets. Chemical, heat treatment and grain refinement.