The alumina ceramic foam filter used for aluminum casting is one of the core components of the ceramic filter. It is a new type of porous functional ceramic material, which is covered with crisscross capillary pores (about 1 to 10 microns in diameter). This is the channel for filtration. This component is called the board base layer. The composition of the ceramic filter plate is silicon carbide, corundum, and other materials. The main components of the ceramic foam filter plate outlet and the positioning base are composed of stainless steel or polymer materials.

Advantages of Alumina Ceramic Foam Filter for Casting

Uniform pore size, high porosity, correct sintering, high bending and compressive strength, and effective filtration.

It is widely used in continuous casting, semi-continuous casting, gravity casting, and low pressure casting aluminum flux filter equipment.

The pore size of the ceramic foam filter ranges from 10 to 60ppi, with different sizes and shapes.

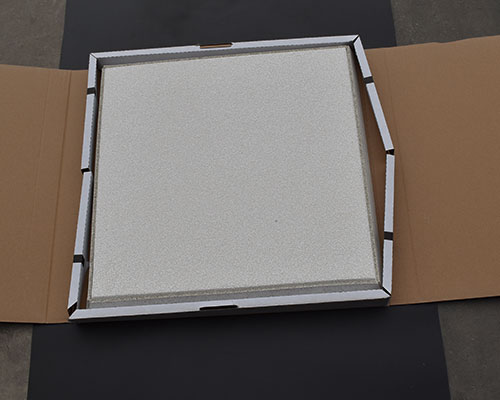

Remove the AdTech ceramic foam filter, there is only a small amount of white powder in the cardboard.

The asbestos sealing edge around the AdTech ceramic foam filter is of good quality and meets the requirements of use.

Ceramic foam filter-light transmittance detection

Take the AdTech ceramic foam filter, compare it with a flashlight, and observe the uniformity of light transmission on the other side of the filter. No blind spots are found, and check whether the transmittance meets the requirements for use.

Net foam filter purge

Use compressed air to purge the slag on the surface of the AdTech ceramic foam filter.

Installation of reticulated foam filter

Gently place the AdTech alumina ceramic foam filter into the CFF filter box, and then press the sealing gasket around the AdTech ceramic foam filter by hand. The surrounding environment is tight without gaps and sealed with refractory mud.