The alumina ceramic foam filter product is suitable for the production of high-quality and high-demand aluminum strips, rods, ingots, and foils. Through physical adsorption and chemical action, it can effectively remove all kinds of oxidation inclusions produced in the aluminum smelting process, thereby reducing casting defects, improving casting quality, and providing high-quality materials for the next step of deep processing.

The ceramic foam filter of our company is carefully developed by adopting the technology of many foreign companies, introducing foreign production equipment and some raw materials. Its performance reaches or exceeds the level of similar foreign products.

Alumina Ceramic Foam Filter use good portiforium foam and high purity ceramic as raw material, can removes non-metal solid mixture from molten aluminium and aluminium alloy fusant effectively in your aluminium casting industry.

Alumina Ceramic Foam Filter Product Function

- It can effectively eradicate large inclusions in molten aluminum.

- It can remove small inclusions of a few microns in size in the aluminum liquid.

- Reduce the hydrogen content in molten aluminum.

- Through adsorption, the content of harmful elements in molten aluminum (Na.k) can be removed.

Alumina Ceramic Foam Filter Uses

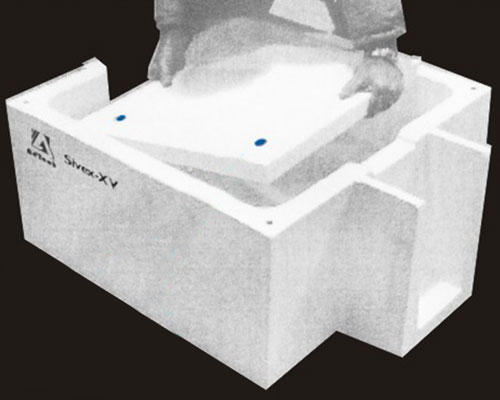

The filter should be completely sealed in the CFF filter box to ensure that all the aluminum water passes through the filter plate. And press the sealing gasket around the filter plate by hand to prevent the aluminum liquid from flowing by.

The alumina ceramic foam filter should be preheated before use. Preheat the filter box and the filter plate evenly to make them close to the casting aluminum liquid temperature.

The total amount of filtration must not exceed the limit. If the slag content in the aluminum water is too high, It should be adjusted by multi-piece filtration or reduced throughput.

After filtering, take out the filter plate in time and clean the filter box.