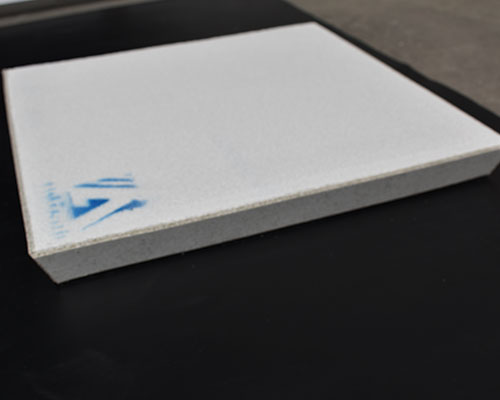

Alumina Molten Metal Filter can effectively remove large inclusions in molten aluminum, adsorb micron-level fine inclusion particles, improve surface quality, improve product performance, improve organization structure, and increase yield. Alumina ceramic foam filter molten metal filtration is widely used in the production fields of aluminum profile, aluminum foil, aluminum alloy and so on.

Porosity of alumina meolten metal filter is the percentage of the total volume of the cavity in the filter plate product to the total volume of the filter plate product. The porosity determines the filtration capacity of the foam ceramic filter plate per unit volume. The greater the porosity, the greater the filtration flow rate of the filter plate, and the stronger the filtration capacity.

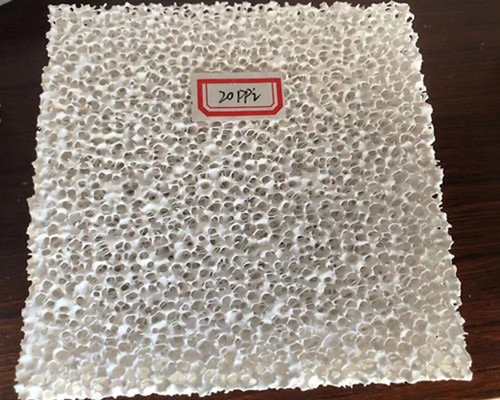

Ceramic foam filters are basically divided into 6 pore sizes: 10PPI, 15PPI, 20PPI, 25PPI, 30PPI, 40PPI, 50PPI, 60PPI. The larger the number, the smaller the aperture. But in actual practice, the four types of 10PPI 20PPI 30PP 40PPI can meet the needs of customers.

10 PPI cast metal filter means that there are 10 honeycomb holes on a square inch of filter sponge. The 30PPI filter sponge has 30 small holes in one square inch. The larger the value, the smaller the hole. Generally, 15-20 PPI is large pores, 25-30 PPI is medium pores, and 35 PPI and above are small pores. The 10-50Ppi alumina ceramic foam filter has a porosity of over 97% and an open porosity of 99%. Good air permeability and high mechanical strength. Therefore, it has the characteristics of small flow resistance and high filtration efficiency.

Alumina Molten Metal Filter Application:

1. The casting: 10~25ppi

2. Semi-continuous casting: 30~60ppi

3. High-quality aluminum or sheet: 50~60ppi

4. Continuous casting and rolling: 50~60ppi

Adtech alumina ceramic foam molten metal filter has the characteristics of light weight, high mechanical strength, large specific surface area, high porosity, good thermal shock resistance, corrosion resistance, excellent performance, and competitive price. It is specially designed for filtering liquid metal impurities.

Due to the distributed pore network structure, the specific surface area can be increased, the sintered ore can be absorbed, the liquid metal becomes purer, and the waste quality problems such as sand holes and air holes are greatly reduced.

The molten metal filter can make the aluminum liquid fill the cavity more uniformly, and the molten metal has a greater tendency to turbulence during the casting process.