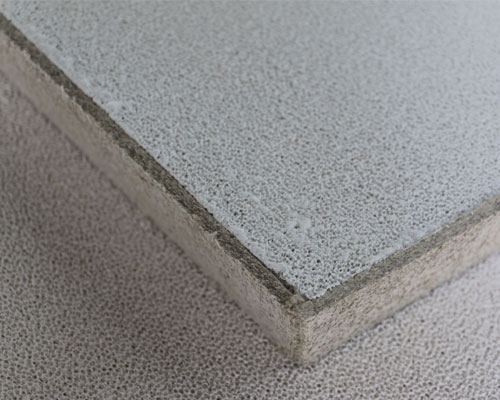

Alumina’s porous ceramic foam filter offers several key benefits that improve the quality of premium aluminum castings. These include:

* improved mechanical properties;

* reduced dye-penetrant indications;

* reduced x-ray evidence of nonmetallic;

* reduced rework/scrap;

* improved machining properties.

Alumina porous ceramic foam filter is mainly used in foundries and cast houses. With their excellent resistance to attack and corrosion from molten aluminum, they can effectively remove inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

The presence of nonmetallic inclusions is detrimental to the production of premium quality castings. High attainable mechanical properties are a key aspect that is readily lost in the presence of inclusions and oxide skins. The mechanical properties of high-strength aluminum alloys are very sensitive to notches or imperfections in the casting. Filtration effectively reduces inclusion levels and subsequent notch effects caused by inclusions. Conventional techniques for attempting to remove inclusions are ineffective, and the use of metal or fiber screens isn’t sufficient to keep the metal truly free of harmful nonmetallic.

Premium quality castings generally restrict the acceptability of surface defects that are revealed by dye penetrant inspection. Research has shown the level of such defects is reduced when ceramic foam filtration is involved. A marked decrease or total elimination has been noted.

Another benefit that is gained from the use of an alumina porous ceramic foam filter is the reduction in the x-ray evidence of non-metallics. The presence of x-ray defects under these circumstances is often the basis for the rejection of expensive castings. The most significant benefit is the reduction of defects visible in those areas that are designated as “structurally critical.”

At Adtech, the continual quest is to ensure that our customers receive the best technology available on the market to produce the highest quality billet, slab, or ingot for their customers. Our guarantee does not stop with our customers, but continues with our customer’s customers! Our technology guarantees conformance of casting quality for the most critical end-product applications.

AdTech is one pioneer followed by the International Enterprise, which keeps focusing on the manufacture of the metallurgical material.

1. Ceramic Foam Filter PAL

2. Degassing Unit

3. Filter Box

4. Hot-top casting series

5. Roll casting nozzle

6. Flux series

7. Other Metallurgical Material