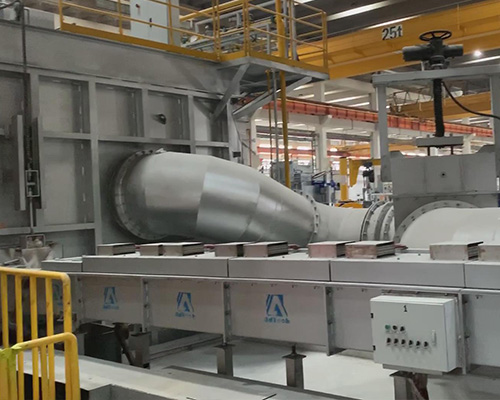

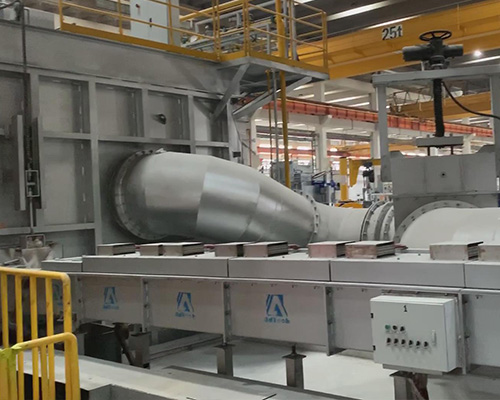

Aluminium Casting Launder is the channel through which the molten aluminum flows from the static furnace to the casting platform. In order to avoid the heat dissipation of molten aluminum, it is required that the launder should have good thermal insulation. When ensuring the length of the process, the length of the launder should be as short as possible, and it is best to be airtight. This can not only prevent the melt temperature from dropping too much, but also avoid the secondary pollution of the melt. In order to facilitate maintenance, the launder is usually made of movable type, the outer shell is welded with steel plate, and the inner lining is made of aluminosilicate clay and asbestos wool. In order to maintain the temperature of the molten aluminum, the launder can be covered with thermal insulation refractory materials, or a resistance wire or silicon carbide rod heating device can be installed on the launder.

A thermal insulation cover is added on the production launder, which obviously plays a role in thermal insulation. The temperature difference between the original boat-shaped ladle and the furnace eye is more than 20 °C, and the current temperature difference is 5 °C. In this way, during the mixing process of ingredients, the temperature of the molten aluminum in the mixing furnace can be controlled to about 750°C, which not only reduces the burning loss, but also saves energy.

Asbestos refractory material with good thermal insulation performance is used as the lining of the launder to replace the casting material with poor thermal insulation performance. The asbestos refractory material is a 700mm long forming material, which can be replaced separately for the bad ones, and it is convenient to replace and save cost. The launder also has a spare launder. For the launder that is seriously deformed and cannot be repaired, it can be replaced as a whole. The replacement is convenient and fast, which greatly reduces the labor intensity and improves work efficiency.

The outer wall of the launder is welded from steel. The interior is made of special refractory materials according to a certain size, which has a good heat insulation effect, ensuring that the molten aluminum can flow quickly, safely and stably, reducing heat loss and keeping the temperature of the molten aluminum in line with casting conditions.

The launder baffle is installed just above the aluminium casting launder and is mainly used for accumulating current at the beginning of casting. In order to ensure that enough molten aluminum with uniform temperature can be evenly distributed to each mold at the beginning of casting, it is designed so that the molten aluminum level will not be too low. The baffle is driven by a coupling, and the baffle is wrapped by a refractory asbestos rope to prevent the leakage of aluminum liquid.