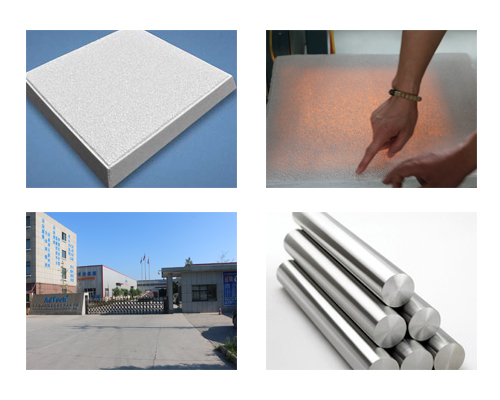

The molten metal aluminium filter is mainly ceramic foam filter. The ceramic foam filter is a filtering device that uses ceramic foam as the filter medium. Ceramic foam is an open-cell mesh with a sponge-like structure for filtering aluminum melt.

The ceramic foam filter is installed in the molten aluminium filter box between the static furnace and the casting table. The depth of the filter box is generally not less than 200mm. The molten aluminum flows from the static furnace to the crystallizer after being filtered by the filter box.

The flow characteristics of ceramic foam depend on the pore characteristics and the size of the ceramic plate. For a ceramic foam filter board with a size of 305mm×305mm×50mm and a number of holes of 30 holes/in, the filtration capacity is about 1.7 – 3.0 kg/s. When filtering aluminum melt, the main filtration parameters of foam ceramics are filtration accuracy 2um, filtration efficiency 99%, initial pressure head 50~150mm, and effective working pressure head 50mm. It can be seen from the above that the foam ceramic filter has the advantages of high filtration accuracy, high filtration efficiency, light weight, small footprint, convenient operation and use, and good working conditions. However, the foam ceramics are discarded once used and cannot be regenerated, and the texture is relatively brittle, so the mixing of fragments should be avoided during installation.

Aluminium Ceramic Filter Advantages:

- Has excellent corrosion resistance and oxidation resistance;

- Good heat resistance, no thermal deformation, it can still be used at 1000 ℃;

- The rigidity is large, the shape does not change under the pressure of the liquid, and the pores are not deformed:

- The filtered material will not be contaminated.

Because of these advantages, it is widely used in food, medicine, molten metal filtration, powder transportation, environmental protection, dust collection, sewage treatment, radioactive waste treatment, and other fields.