Aluminum processing has higher and higher performance requirements for aluminum products or semi-finished products in recent years. The quality of the aluminium melt is a key factor in the production of semi-finished or final products. AdTech has developed different equipment in the technology of adopting various aluminium alloy melt purification measures to remove gases and inclusions. The comprehensive performance requirements for aluminum melts focus on maximizing the removal of hydrogen, inclusions, and alkali metals in the aluminium melt.

In terms of melt processing, because it is related to the type of cast alloy, the type of production plant (remelting plant, foundry, etc.), or the type of product produced and cast (slab ingot, extrusion bar, cast component, etc.), In terms of alkali metal content and dehydrogenation, according to the different requirements of aluminum processing enterprises for melt purification, use:

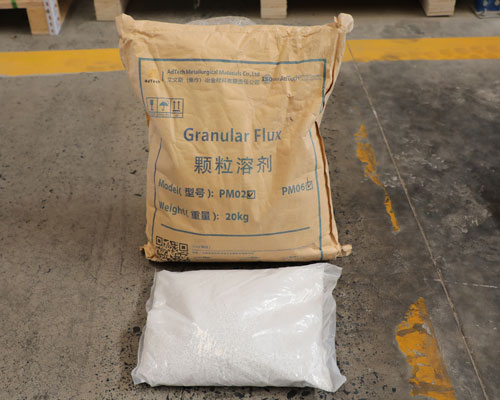

Granular refining agent: In the smelting furnace and holding furnace, the granular refining agent is used and nitrogen is used as the carrier gas to remove alkali metals and impurities in the molten aluminum in the furnace.

Online degassing system: Melt treatment is carried out in the degassing box to remove hydrogen and impurities. Through the control of alkali metal and hydrogen in the aluminum alloy melt, it meets the needs of users to improve the quality of ingot products.

On-line filtration equipment: Install ceramic foam filter plates in the filter box to further filter the molten aluminum to remove fine particles of impurities.

The cleanliness of aluminum melt, that is, reducing the inclusion of aluminum melt, is a very important factor in the production of high-quality products. The inclusions in the aluminum alloy make the alloy structure discontinuous, reduce the compactness of the product, cause corrosion and cracks, and reduce the mechanical properties of the final product.

With the gradual development of industrial aluminum applications, products have higher and higher technical requirements for melt processing, and aluminium melt purification equipment is required to comply with the environmental protection policy of producing green aluminum. Only by continuously improving the equipment and technology of aluminum melt purification can we meet the higher quality standards of users and maintain sustainable competitiveness in the production of high-performance and high-quality materials. AdTech is committed to continuously improving melt processing and control technology, providing a full range of melt purification equipment, and adopting green technology to achieve sustainable development of environmental protection and efficiency in the aluminum processing industry.