The aluminium metal filtration technology is to filter out the inclusions contained in the alloy as much as possible. In this way, due to the reduction of inclusions, the plastic zone at the crack tip is enlarged, which leads to an increase in the resistance to crack propagation and the performance of the aluminum alloy.

Before the aluminum alloy is filtered, it contains a lot of inclusions. These inclusions often form micropores and promote the propagation of cracks. These inclusions will increase the viscosity of the alloy liquid and reduce the fluidity. When the molten metal is solidified, the feeding channel between the dendrites is easy to be blocked, forming tiny shrinkage cavities and looseness. These are the reasons that cause the performance of the alloy to decrease.

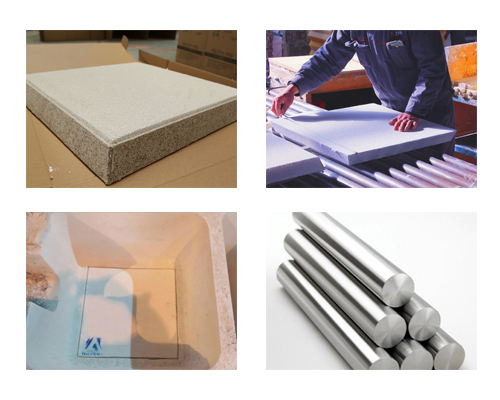

Foam Ceramic Filter has many advantages such as good chemical stability, high specific strength, high temperature resistance, thermal shock resistance, and large specific surface area. It is widely used in the aluminum melting and casting metallurgy industry.

In metallurgy, ceramic foam filter aluminium metal filtration can remove foreign contaminants in the lead melt, such as slag and inclusions, which is one of the most effective melt cleaning methods.

As the requirements for the quality of aluminum products are getting higher and higher, the requirements for the ceramic foam filter are getting higher and higher.

Choosing the right ceramic foam filter plate is an important task. The size of the filter plate depends on the flow rate and total amount of the filtered metal. Semi-continuous casting mainly considers the flow rate of metal, while continuous casting mainly considers the total amount of metal. In the effective filtration area, the metal flow rate per square centimeter minute should be 70~210g. When the filtered metal flow rate exceeds this range, the filtration efficiency and the ability to capture debris are drastically reduced. As the pore size of the filter plate decreases, the size of the trapped impurities also decreases, and the efficiency of filtering and removing impurities increases.