Aluminum alloy casting performance refers to the performance of molten aluminum in the process of full casting, crystallization and cooling. It has fluidity, shrinkage, airtightness, casting stress, and getter. These characteristics depend on the composition of the alloy, but also relate to casting factors, alloy heating temperature, the complexity of casting, gate riser system, gate shape, etc.

Aluminum Alloy Casting Performance

Aluminum alloy casting performance includes Fluidity, Contractility, Thermal Cracking, Air tightness, Casting stress, Inspiratory.

Fluidity

Flowability refers to the ability of the alloy liquid to fill the mold. The size of the fluidity determines whether the alloy can cast complex castings. The eutectic alloy has the best fluidity among aluminum alloys. There are many factors that affect the fluidity, mainly the composition, temperature, and solid-phase particles of metal oxides, metal compounds, and other pollutants in the alloy liquid. But the external fundamental factors are the pouring temperature and the pouring pressure. In actual production, in addition to strengthening the smelting process (refining and slag removal), it is also necessary to improve the moldability and increase the pouring temperature without affecting the quality of the casting, so as to ensure the fluidity of the alloy.

Contractility

Shrinkage is one of the main characteristics of cast aluminum alloys. Generally speaking, the alloy is divided into three stages from liquid casting to solidification and cooling, which are liquid shrinkage, solidification shrinkage, and solid shrinkage. The shrinkage of the alloy has a decisive influence on the quality of the casting. It will affect the gradual shrinkage hole size, the production of stress, the formation of cracks, and the change in size.

Thermal Cracking

The occurrence of thermal cracks in aluminum castings is mainly due to the shrinkage stress of the castings exceeding the bonding force between the metal grains. Most of them are generated along the grain boundaries. From the crack fracture, the metal at the crack is often oxidized and loses its luster. The cracks extend along the grain boundary, and the shape is zigzag, the surface is wider, the interior is narrower. So some penetrate the end face of the entire casting.

Air tightness

The airtightness of the cast aluminum alloy refers to the degree to which the cavity type aluminum casting does not leak under the action of high pressure gas or liquid. The airtightness actually indicates the degree of compactness and purity of the internal structure of the casting. The airtightness of the cast aluminum alloy is related to the properties of the alloy. The smaller the solidification range of the alloy, the smaller the tendency to loosen, and the smaller the precipitating pores, the higher the airtightness of the alloy.

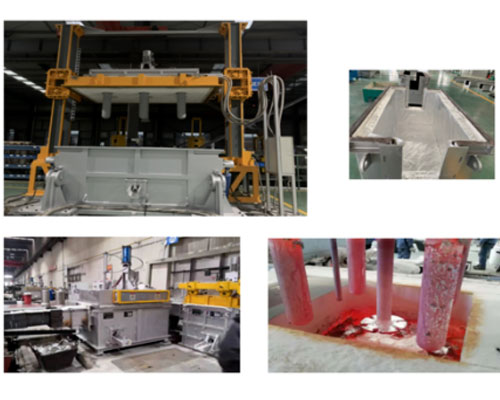

The higher the hydrogen content in the aluminum alloy liquid, the more pinholes are produced in the casting. The pinholes in the aluminum casting reduces the airtightness and corrosion resistance of the casting, and also reduces the mechanical properties of the alloy. The key to obtaining aluminum castings with no or few pores is the melting conditions. If add covering agent during smelting, the inspiratory volume of the alloy is greatly reduced. Refining aluminum liquid can effectively control the hydrogen content in the aluminum liquid. AdTech online degassing unit adopts new high silicon melting material manufacturing technology, it can effectively degas the aluminum liquid.

Casting stress

The casting stress includes thermal stress, phase transformation stress and shrinkage stress. The thermal stress is caused by the uneven thickness and the inconsistent cooling. The compressive stress is formed at the thin wall, resulting in residual stress in the casting. The phase change stress is due to the phase change during the cooling process after solidification, and the resulting change in volume and size. Shrinkage stress is caused by the tensile stress caused by the obstruction of the mold and core when the aluminum casting shrinks. This stress is temporary, and the aluminum casting will automatically disappear when unpacking.

However, improper unpacking time will often cause thermal cracking, especially aluminum alloys cast in metal molds are prone to thermal cracking under such stress. The residual stress in the cast aluminum alloy reduces the mechanical properties of the alloy and affects the machining accuracy of the casting. The residual stress of aluminum castings can be removed by annealing.

Inspiratory

Aluminum alloys easily absorb hydrogen gas, and inspiratory is the main characteristic of cast aluminum alloys. The higher the temperature of the aluminum alloy solution, the more hydrogen is absorbed. At 700 ° C, the solubility of hydrogen per 100g of aluminum is 0.5-0.9. When the temperature is increased to 850 ° C, the solubility of hydrogen increases by 2-3 times. When containing alkali metal impurities, the solubility of hydrogen in the aluminum liquid increases significantly.

In addition to gettering during melting, cast aluminum alloys also generate gettering when pouring into the mold. In addition to gettering during melting, cast aluminum alloys also generate gettering when pouring into the mold. With the temperature of liquid aluminum decreases, the solubility of the gas decreases, and excess gas is precipitated. A part of the unavoidable gas is left in the casting to form air holes, which is commonly called “pinhole”. The gas is sometimes combined with the shrinkage cavity, and the gas precipitated in the aluminum liquid remains in the shrinkage cavity.

If the pressure generated by the bubble is very large, the surface of the pore is smooth, and there is a circle of bright layer around the hole. If the pressure generated by the bubble is small, the inner surface of the pore is wrinkled.