Aluminum Casting Filter Media is critical for aluminum foundries. Some foundries use deep bed filters for products. The final filtration step is usually ceramic foam filter (CFF). This usually involves filtering molten aluminum through ceramic media beds of different sizes. Although these are usually very effective (usually more than 85%), they can be expensive to operate. This is due to the required floor space and limited service life of the filter media. They usually need to be replaced and disposed of on a regular basis.

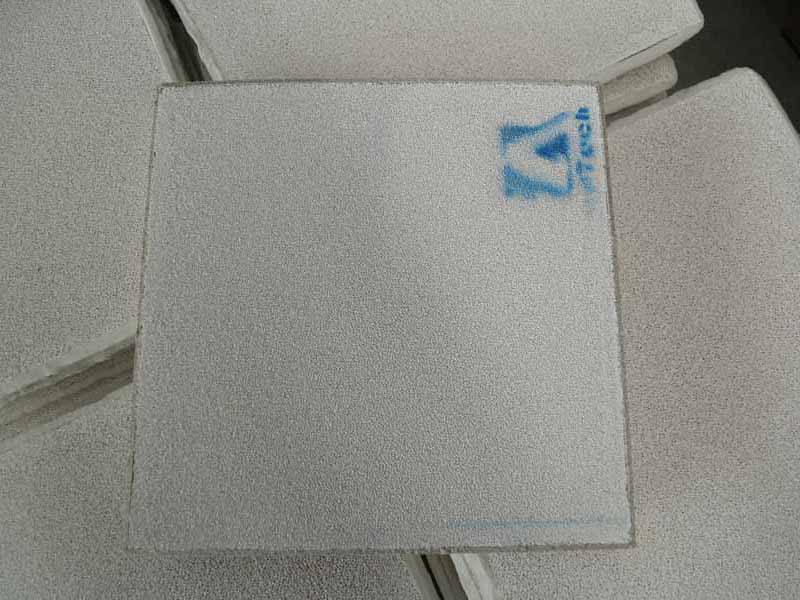

The final filtration step is usually ceramic foam filter (CFF). This disposable filter is made of rigid porous ceramic foam and has a strictly controlled aperture. Due to their simple operation and good short-term results, these are usually the only filtration equipment in many foundries. The three key parameters of CFF are as follows:

- Filtration area – the larger the area, the greater the potential metal flow. However, due to the risk of damage, large tiles may be difficult to handle.

- Aperture – the smaller the aperture, the higher the efficiency of the filter. But it’s more likely to stop mid-term actors.

- Thickness – the thicker the filter, the better the filtration efficiency. However, starting it initially can be more difficult.

For some extremely critical applications, more expensive Aluminum Casting Filter Media – ceramic tube filters are often used.

Regardless of the type of filter used, care must be taken to ensure that the filter is not affected by excessive vibration or metal level changes. These “interferences” can lead to the release of inclusions, which may eventually lead to inclusions in the finished product. Good process control downstream of the final filter is particularly important. If maintenance is required, this should include careful cleaning preparation with special attention. In addition, foundry operators should be careful to minimize turbulence in some areas, such as around metal distribution bags.

Even with the best available filtering technology, the very dirty metal you enter can be overwhelming. Therefore, the importance of proper treatment of metals before filtration should not be overstated. The cleaner the metal that enters the filter, the finer the filter that can be used, causing “even cleaner” metal to leave the filter.