In many industrial production processes, especially metal smelting, various refining agents are added to improve the performance advantages of products. Regardless of whether it is the pharmaceutical industry or the metal industry, refining agents are one of the common solvent products, mainly white powders or granules, which are processed by a variety of inorganic salts in a certain proportion. So, what do you know about the role and use of aluminum casting refining agent?

Aluminum Casting Refining Agent Uses

Adding an appropriate amount of refining agent when smelting aluminum products can effectively remove the hydrogen contained in the aluminum liquid and the floating oxide slag. The main reason is that the refining agent is easy to decompose at high temperature, especially the produced gas is prone to chemical reactions, and the strong adsorption capacity of slag inclusion can allow hydrogen to escape from the melt, so it can achieve a clear slag removal effect. It is a good choice for companies that have relatively high requirements for smelting pure aluminum, and has been unanimously praised and recognized by customers and friends.

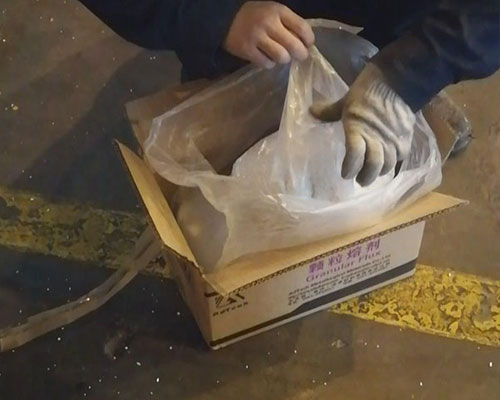

In fact, the use of refining agent is relatively simple, you can learn more about its use before use. Especially, evenly sprinkle it on the liquid surface, quickly press it into the molten aluminum, mix it well and let it stand for slag removal. In the process of use, you can use a sprayer. It will be better to use inert gas to spray it. The dosage is about 0.3% of the weight of the aluminum liquid. If the purity of the aluminum liquid is relatively high, please add more Refining agent.

In the smelting of aluminum alloy, an appropriate amount of refining agent will be added, because it can play a role in degassing and removing impurities, making the aluminum alloy solution more pure and improving its mechanical properties. There are many precautions for adding refining agent, the following is an introduction to the specific usage method.