Aluminum liquid filter can effectively remove the bubbles, ash oxides, and all kinds of assimilates and other harmless impurities in the aluminum melt. It can greatly improve the product rate and quality of aluminum castings, and prevent the defects of other metal components penetrating into the aluminum solution, which will not affect the aluminum alloy factors, so as to ensure the quality of aluminum castings. The hardness and contour hardness of the casting can be increased, and the bending strength can be increased.

Molten metal filtration is the most effective and reliable method to remove non-metallic inclusions in aluminum alloy melt. In principle, it can be divided into cake filtration and deep filtration. There are many kinds of filtration, the best ones are filter tube and foam ceramic filter.

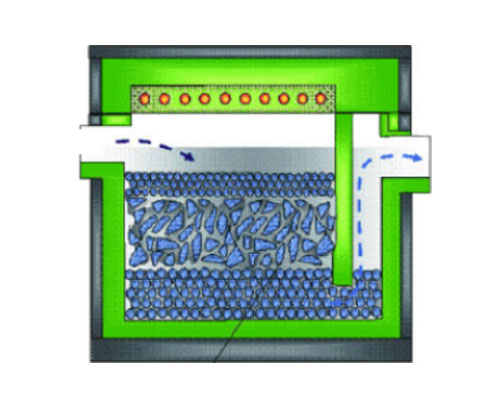

Due to its large volume, time-consuming and laborious to install and replace the filter media, the bed type transition device is only suitable for the production of a large number of single alloy. Therefore, there are few manufacturers using it. Its latest development is the compact deep bed filter being developed by Norway University of science and technology. In the device, the liquid aluminum flows downward. A vent plug at the center of the bottom of the device is added with emotional gas, which forms a gas lift pump with the aluminum liquid rising pipe above the vent plug, which can adjust the metal level at the outlet, so as to improve the filtration efficiency and make more effective use of the filter ball. The device is compact and compact and easy to fill, empty and move.

Corundum tube filter has high efficiency, but it is expensive and inconvenient to use, so it is widely used in Japan. The corundum tube transition device was developed by Southwest Aluminum Industry (Group) Co., Ltd. in 1980s, but the filtration effect was not stable due to assembly quality and other reasons, so it was no longer used in the 1990s. The technology has not been further developed in recent years.

On the contrary, the ceramic foam filter plate is widely used all over the world for its convenience, good filtering effect, and low price. More than 50% of aluminum alloy melt in developed countries is filtered by foam ceramic filters. The technology is developing rapidly. In order to meet the requirements of high-quality products for melt quality, the pore diameter of the ceramic foam filter plate is becoming smaller and smaller. The products of Adtech have developed from 20ppi, 30ppi, 40ppi, 50ppi to 60ppi and 70ppi. At the same time, many new products are available. AdTech foam ceramic filter plate technology has been widely accepted by the market.

For the products with high quality requirements, the transition of two-level foam ceramic filter plate is widely used in developed countries. The filter board at the front level is relatively thick, and the upper level transition board has a smaller pore diameter, such as 30/50ppi, 30/60ppi and even 40/70ppi configuration. China’s Southwest Aluminum Industry (Group) Co., Ltd. double zero aluminum thin, PS plate base, cans and other products melt is also 30/50ppi two-level foam ceramic transition plate filtration.