Aluminum melt filtering technology can reduce impurities and inclusions in the melt before casting. The quality of aluminum melt treatment will affect the quality of the ingot product, and affect the subsequent processing and product material quality. Therefore, aluminum melt filtration technology is an important part of the production technology of aluminum processing materials. Aluminum melt filtering devices are the application of this technology. At present, the commonly used aluminum melt filtering devices include three types: ceramic foam filter box (CFF), deep bed filter (DBF), and porous tube filter (PTF).

Aluminum Melt Filtering Devices

CFF Foam Ceramic Filter Box

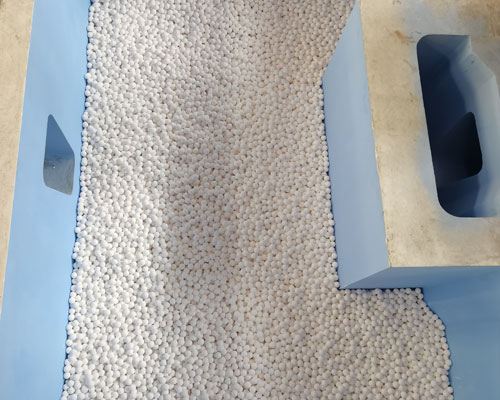

The CFF ceramic foam filter box is composed of a filter box body and CFF. The filter box body is composed of multilayer refractory materials and steel structure. The refractory material in contact with the melt is generally made by casting a non-stick aluminum casting material at one time. The foam ceramic filter plate is injected into the plastic sponge with a mixed slurry of alumina and phosphate. After drying and sintering, the plastic sponge is volatilized, so tortuous channels and pores are formed in the filter plate.

Deep Bed Filter (DBF)

The deep bed filter is composed of the main body of the filter box and the main body of the deep bed filter bed. The composition of the main body of the filter box is similar to the shell of the foam ceramic filter box, but the shape of the shell is different.

Porous Tubular Filter (PTF)

The porous tubular filter is composed of a filter box and a tube group, and its characteristics are similar to the deep bed filter box. In order to extend the use effect of the filter tube, some aluminum foundries have added a foam ceramic filter plate in front of the tubular filter, so as to filter out large-size impurities and inclusions.

Currently, the foam ceramic filter plate is the most widely used in aluminum foundry. The ceramic foam filter price is low, and filter plates of different PPI can filter out impurities of different sizes, so it can extend the service life of other filter equipment.