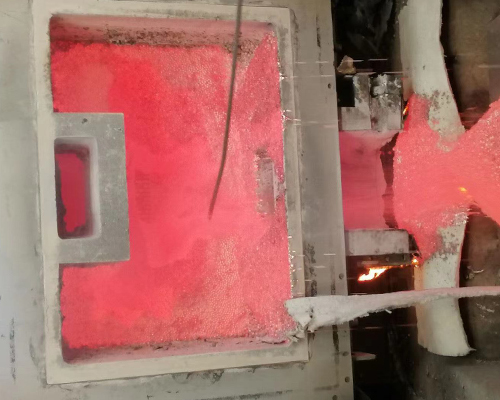

Aluminum melt filtration and purification is the use of filtration technology to reduce the impurities and inclusions in the melt before the melt is cast and rolled. The quality of aluminum melt treatment will affect the quality of cast-rolled products, and further affect the quality of subsequent processed products. Commonly used aluminum melt filtering devices include plate ceramic foam filter equipment, deep bed filtering equipment, and tubular filtering equipment.

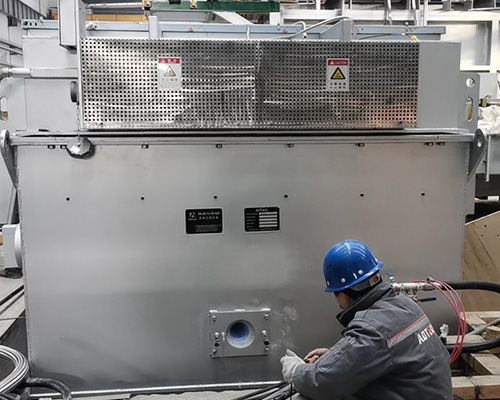

The ceramic foam filter box is composed of a filter box body and a CFF filter plate. The filter box body is composed of multiple layers of refractory materials and steel structure. When the melt flows through the filter plate, impurities and inclusions are filtered out. The service life of a single filter plate depends on the size of the filter plate, the number of holes and the cleanliness of the metal. For a single filter plate, the size and number of holes are fixed. In order to improve the filtration effect, some manufacturers consider two-stage filtration, which is generally used in combination with the front coarse and the fine. The filtration effect is good. For impurities and inclusion particles of about 20-30u, the removal rate can reach 75% ~ 90%. More flexible. The cleaning of the filter box and the replacement of the filter plate are simple, convenient and fast, and it is very flexible in the production of various alloys.

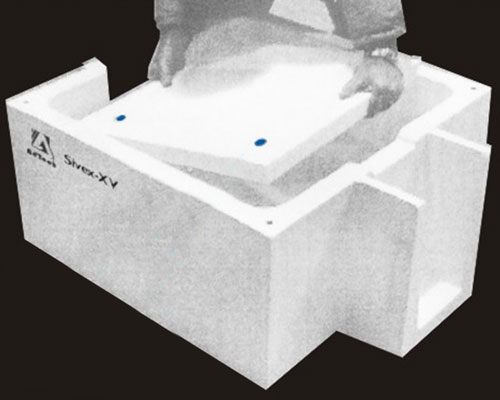

The deep-bed filter is composed of a filter box body and a deep-bed filter bed. The structure of the filter box is similar to the foam ceramic filter box, but the difference is that the shape of the refractory material in the box is different. The deep bed filter is equipped with electric auxiliary heating, which can effectively prevent the temperature drop in the box and play a certain role in heat preservation for the melt. Better metal temperature control can reduce oxidation or hydrogen absorption. Proper preheating of the molten metal before entering the filter is beneficial to the lining of the box.

The tubular filter is composed of a filter box body and a filter tube group. The structure of the filter box is similar to the deep bed filter. The porous tubular filter is also equipped with electric auxiliary heating, which has the same advantages as the deep bed filter.

In addition to gas, the aluminum melt also contains inclusions. The inclusions are brought into the ingot from the smelting and casting process. They reduce the purity of the metal, destroy the continuity of the metal, and make the mechanical properties, stress corrosion resistance is reduced. Inclusions are generally 1~30um, if they are not removed, it is impossible to produce high-quality products. During the on-line degassing process, the air bubbles meet with the inclusion particles through the floating process of the bubbles, so that some of them are carried out of the surface, and the remaining inclusions need to be removed by the filter device. At present, aluminum melt filtration and purification is the most effective method to remove non-metallic inclusions in molten aluminum and aluminum alloys.

Because deep bed filter equipment and tubular filter equipment are expensive, in order to extend their use effect, aluminum foundries will add ceramic foam filters before these filters to filter larger size impurities.