Since inclusions and hydrogen in molten aluminum are accompanied and interacted with each other, various methods based on hydrogen removal and purification also have different degrees of impurity removal. However, practice shows that this kind of impurity removal effect is very limited. In order to effectively remove impurities, there are not many aluminum purification methods at present. It is not as deep as the research depth of hydrogen removal purification, mainly including flux method, electric flux method, and filtration method.

Aluminum Purification Methods

The essence of the flux method is that when the molten aluminum is purified by the flux, the inclusions will spontaneously migrate from the melt into the flux due to the difference in transition between the contacting phases. Its impurity removal effect is directly related to the physical and chemical properties of the flux itself. At the same time, the purification process conditions have not been determined in a large program, such as the amount of flux, the contact conditions of the flux and the melt, and the temperature.

The electric flux method is a purification method developed by the former Soviet Union since the 1970s. Its essence is to continuously remove impurities from molten aluminum under the action of a DC or AC electric field.

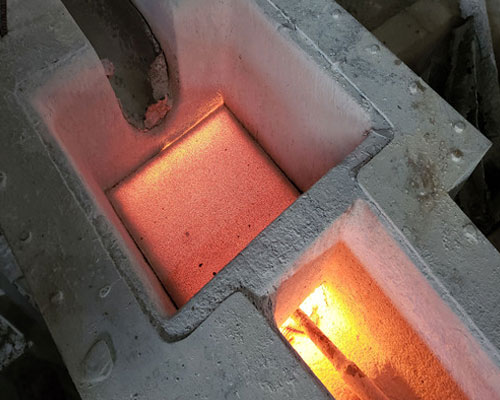

Purification by filtration method is mainly to make the aluminum liquid flow through a certain medium, and the medium captures the inclusions according to a certain mechanism, and at the same time cuts off the hydrogen adsorbed on the impurities to achieve the purpose of purification. It is one of the effective methods to eliminate the inclusions. According to the filter form, it can be divided into three categories: mesh filter, granular filter, porous ceramic filter, among which porous ceramic filter is divided into rigid ceramic (microporous) and foam ceramic filter. According to the filtration mechanism, it can be divided into filter cake filtration mechanism and deep filtration mechanism. Porous ceramics belong to deep filtration.