Round aluminum rods include round aluminum rods for electrician production of electrical aluminum wires and round aluminum rods for production of extruded round pipes. In general, the production process of the two round aluminum rods is roughly the same, including the steps of batching, furnace loading, temperature control, composition adjustment, continuous casting, continuous rolling, rod receiving, inspection and storage. Round aluminum poles for electricians require certain strength, low resistivity and good elongation. To meet this requirement, the molten aluminum must not contain too many oxide inclusions and gases, otherwise, there will be billet breakage during the production process of aluminum rods, making the production process unable to proceed normally. Round aluminum rods used in the production of extruded round tubes have higher requirements for molten aluminum, and there must be no defects such as pores and inclusions in the aluminum rods.

According to the production requirements of round aluminum rods, the aluminum liquid must be strictly purified from each process.

(1) Process control of vacuum bag aluminum extraction: The aluminum extraction process must be carefully operated to avoid introducing other impurities.

(2) Purification in the open bag: When the aluminum tap carries the molten aluminum to the holding furnace, the oxide slag on the surface of the molten aluminum must be cleaned.

(3) Melt purification in the furnace: The purification in the holding furnace is the most important place to purify the molten aluminum. Nitrogen sprayed powder solvent refining method can be used. Let the molten aluminum fully stand, generally not less than 30 minutes, so that impurities and gases have enough time to float or sink. After refining, spread the covering agent evenly on the surface of the molten aluminum.

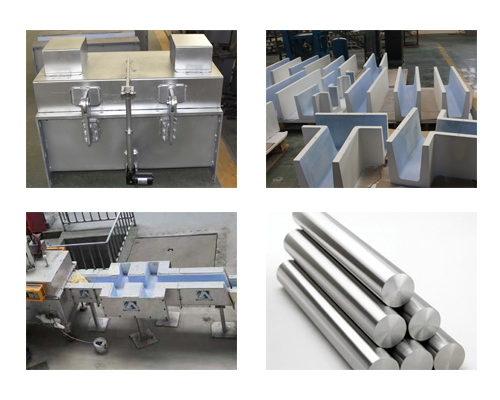

(4) Melt purification of the casting system: The melt purification of the casting system can prevent secondary pollution of the aluminum liquid from inhalation, oxidation, slagging, and inclusions from the furnace to the mold. First of all, the casting launder should use a good formed thermal insulation lining, and the surface should be pasted with an aluminum silicate fiber blanket to avoid inclusions when the aluminum liquid is transferred. Secondly, the design of the casting system should be reasonable, and there should be no excessive drop between the aluminum furnace eye and the mold. If the drop is unavoidable, a tundish can be used to avoid column flow. Again, use glass cloth and ceramic foam filter for filtration.