The hot top casting method is widely used in the aluminum round rod casting process. In this way, not only can the contact conditions between the molten aluminum and the mold be improved, but also the cooling effect can be improved, thereby suppressing the coarse structure formed during the casting of the aluminum ingot, thereby suppressing the air gap.

When the molten aluminum starts to be cast, the molten aluminum is first poured from the tank into the water-cooled mold. Therefore, a large number of oxides will be generated during the process of pouring the molten aluminum into the water-cooled mold. In addition, even after the casting start time, the casting process enters a stable state, the oxides produced on the surface of the molten aluminum in the water-cooled mold will also accumulate, and the accumulated oxides will enter the surface layer, and the aluminum alloy ingot will form a recessed part.

If the alloy contains a high concentration of Mg, the problems caused by oxides will become particularly serious.

In order to solve these problems, it has been proposed to treat the molten aluminum with chlorine (Cl2), sulfur hexafluoride (SF6) gas, etc. in advance to suppress the oxidation of the surface of the molten aluminum. However, because this method is carried out in the online refining process, the oxidation effect for inhibiting the surface oxidation of the molten aluminum inside the mold is insufficient.

In addition, because Cl2 is a toxic substance, it will not only cause environmental problems, but also severely aggravate the deterioration of peripheral equipment.

On the other hand, SF6 has a global warming potential value of as high as 20,000, so it is not preferable to use it from the viewpoint of preventing global warming.

In addition, SF6 chemically reacts with hydrogen contained in molten aluminum in the dehydrogenation process using SNIF to generate hydrogen fluoride (HF). Since HF is a highly corrosive substance, it will damage the furnace. In addition, HF is very toxic to organisms. Most aluminum foundries use inert gas (nitrogen or argon) as a protective gas, which can prevent the surface of molten aluminum from being oxidized.

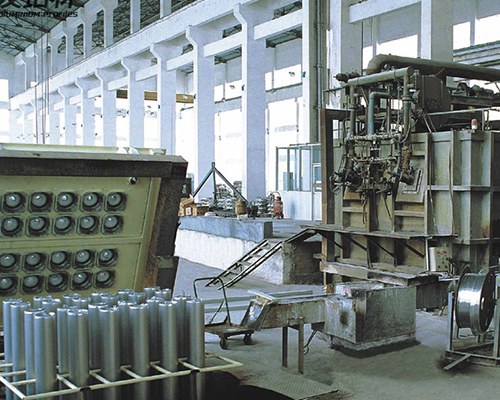

In order to solve these problems, hot top casting is used. The hot top method is a method in which a refractory container having substantially the same shape as the mold is placed on the upper part of the mold, and molten aluminum is stored in the refractory container while casting. In this method, a mold made of graphite is generally used. Using this method, the pressure caused by the molten aluminum inside the refractory container is applied to the inside of the mold. In other words, since the molten aluminum is forced into the mold, it is difficult to form the air, so the method has been applied to the small diameter aluminum round rod casting production.