AdTech provides degassing filtration systems, refining agents, nozzle plates, launders, front boxes, flow control accessories for aluminum strip casting. AdTech produces high-quality refractory materials, and solves aluminum liquid purification problems for aluminum foundries.

AdTech Nozzle Plate is used for the crystallization and size control of aluminum sheet, strip and foil blanks in the casting and rolling production line. It is formed by vacuum suction and filtration of nano-fiber composite materials and processed by high-precision equipment.AdTech Nozzle Plate has an even distribution of internal short fibers, moderate density, good heat preservation, precise size, high oxidation resistance, no delamination and no block loss, low deformation. It can effective protect of cast-rolled coil surface quality, and better effect when used with boron nitride coating.

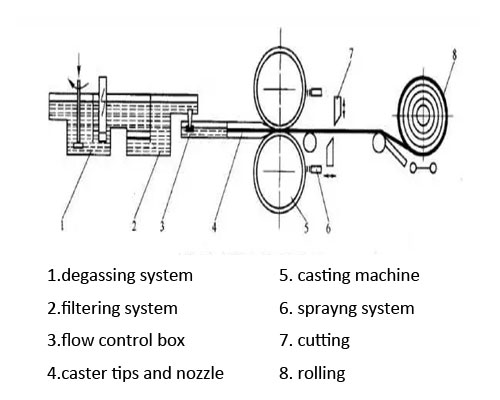

Aluminum Strip Casting Process

The molten aluminum produced by smelting the aluminum ingot through the aluminum melting furnace and the holding furnace enters the molten aluminum degassing and filter device through the molten aluminum launder, and the molten aluminum enters the front box through the launder after degassing and filtering. The molten aluminum in the front box enters the roll gap of the casting mill through the casting nozzle. The two rolls of the casting-rolling mill are cooled by water. The aluminum melt is forced to cool down in the gap between the casting rolls and crystallizes and solidifies, and completes the two processes of solidification and hot rolling by the casting rolls, which are in a short interval (casting zone). ) And a very short time (2~3 seconds) to complete the aluminum strip.

The casting launder between the furnace mouth and the degassing filter device is equipped with liquid level control for the molten aluminum. The aluminum-titanium-boron alloy wire is fed into the launder by the wire feeder to refine the grain structure.

The composition of the aluminum strip continuous casting and rolling unit includes: a smelting furnace group, degassing filter system, pinch roll, casting mill, hydraulic shear, deflector roll, coiler, unloading trolley, etc.