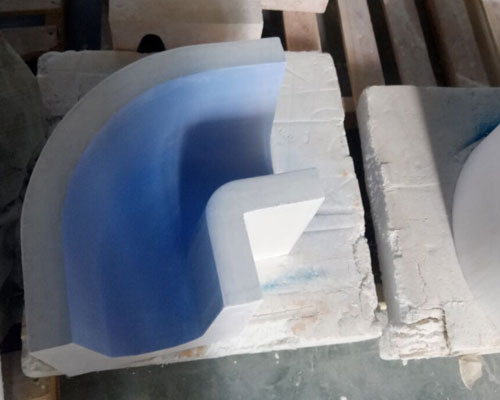

The material of the aluminum transfer launder can be divided into two categories: ceramic fiber and castable. The ceramic fiber launder has the advantages of low density, high specific strength, and good heat preservation. The cast material flow trough has the advantages of high strength, erosion resistance and long service life. AdTech aluminum transfer launder products combine the excellent performance of the two, the launder and trough have good insulation performance, erosion resistance, thermal shock resistance, and smooth surface.

Ceramic fiber launders have the advantages of low density, high specific strength, good thermal insulation, and non-stick aluminum. Different structures of launders can be made of silicate fiber material. With the continuous development of ceramic fiber technology, the use of zirconium-containing The launder made of aluminum silicate has higher strength and higher operating temperature, which is suitable for more demanding environments.

The castable material launder has the advantages of high strength, erosion resistance, and long service life. It is also suitable for the production of launders with different structures. With the continuous development of castable material technology, new types of castable materials continue to emerge, so that the launders, filter boxes, splitter plates and other products prepared from them have also been continuously optimized in terms of heat preservation and density. The castable material launder has been recognized and widely used in the market, and the production process is relatively simple, and there is a trend to replace ceramic fiber materials as the leading product in the aluminum casting market.

Before the casting launder is used, it is necessary to check whether the appearance is damaged, whether there is any crack on the surface, whether the product is flat and smooth, and whether the size meets the drawing standards, and can enter the casting workshop only after passing the inspection.

When replacing the launder and trough, take care to handle it with care. A certain thickness of aluminum silicate paper board should be lined around the iron shell, which can not only insulate the molten aluminum, but also slow the impact of the external force of the launder and extend the service life of the launder. After casting, the residual aluminum in the launder must be cleaned up in time.

When cleaning the aluminum transfer launder system, be careful not to hit or knock the launder. After cleaning, the launder surface is coated with a layer of modulated talcum powder slurry for the next charge to be used for casting. It is worth noting that, due to cleaning, the joints between the runners and runners are often broken, which requires careful inspection and repair with high-temperature inorganic binders.