The metal entering the casting machine must be free of inclusions, and the surface quality of the launder will affect the risk of refractory pieces……

AdTech Box-type online degassing equipment is a high-end online degassing equipment, the equipment adopts PLC and touch screen control, with hydraulic lifting, hydraulic rotation, automatic……

After the molten aluminium filling for a certain period of time, it starts to enter the casting stage. At this stage, the casting speed starts……

After batching, smelting, refining and standing, the 6063 aluminum alloy liquid meets the required chemical composition, casting temperature, and metal purity, and completes the preparation……

The amount of strontium modified is 0.02%~0.06%, the upper limit is taken for sand casting, and the lower limit is taken for the metal type.……

The mechanism of the refining flux method is to absorb and dissolve the oxidized inclusions in the molten aluminum alloy and the hydrogen adsorbed on……

The high-efficiency non-sodium refining agent has the functions of covering, removing slag, degassing, deterioration, and refinement, and can purify molten aluminum. Compared with ordinary refining……

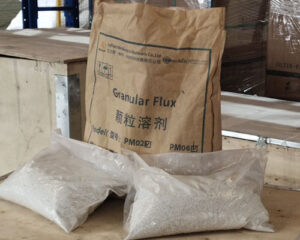

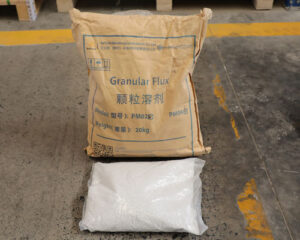

AdTech aluminum granular flux is used for the degassing and slag removal of molten aluminum, which solves the problem of burning caused by chemical reaction……

High-efficiency refining fluxes for aluminum alloy smelting has the following advantages: It has the advantages of combining gas refining and flux refining into one, and……

Non-sodium refining flux is suitable for refining treatment. It is mainly used for refining and degassing various high-strength cast aluminum alloys such as automobile wheels……