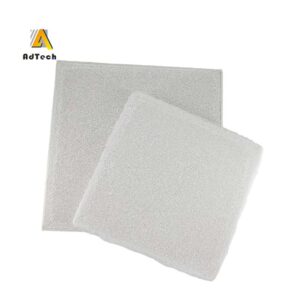

A ceramic foam filter is installed on the CFF filter equipment to filter liquid impurities in the aluminum alloy, so as to meet the production……

The molten Al ceramic filter can effectively remove various inclusions in the aluminum melt with micron fineness, so that the molten aluminum becomes a smooth……

Aluminum foundries usually use ceramic foam filters in their filtration operations. Molten aluminium filter reduces the number of castings that must be scrapped due to……

Due to excellent mechanical properties, processability and recyclability, aluminum and aluminum alloys are widely used in various fields. Aluminum alloys that are produced from waste……

After degassing the molten aluminum, all remaining solids or impurities (such as oxides) must be removed by filtration. Foundries usually use ceramic foam molten metal……

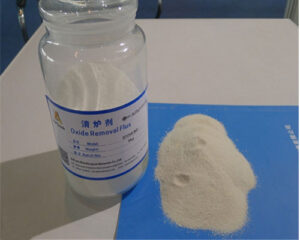

The flux removes dissolved and suspended impurities, including oxides, nitrides, carbides, and carbonates of molten metal and alloying elements. Dissolved impurities include dissolved gases and……

Casting is a common metal and alloy-forming technique where a liquid or molten material is poured into a mould to cool and solidify into the……

Online degassing equipments can improve metal quality, reduce melt loss from dross and optimize cast parts. Online degassing helps remove hydrogen, inclusions and alkali metals……

Degassing of molten aluminum is an essential process in alloy casting. It is done by one of two methods: flux or rotary degassing. The molten……

During the transportation of molten metal alloys, filter media of high temperature resistant materials are used to remove inclusions. The filter medium must be resistant……