Ceramic foam is a good example of a filter medium that is used as a depth filter from the beginning and as a cake filter……

Currently, there are five main types of filters used for aluminum filtration. They are: glass or ceramic fiber woven wire mesh; uncombined plate-like or spherical……

The impurities in the melt have been identified as the main cause of product failure during production and use. Therefore, melt cleanliness becomes a measure……

The firing of the porous ceramic filter materials is usually carried out at a temperature higher than the temperature at which the glass phase of……

The requirement for the production of aluminum ingots and billets for the preparation of high-quality aluminum products is that molten aluminum is relatively free of……

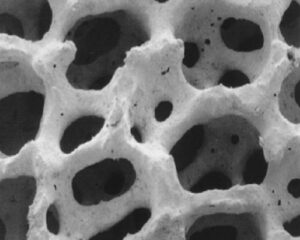

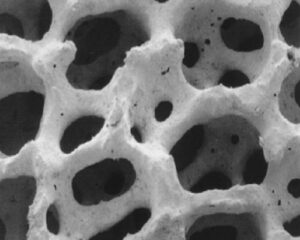

The foam ceramic filter is made by foam replication technology, which is a conventional method of producing ceramic foam used as a molten metal filtering device.……

The purpose of the rotating rotor degassing is to break up the large inert gas bubbles into very fine small bubbles and make them evenly……

In order to remove alkali metal elements (ie Na, Ca, K, Li), the use of chlorine-containing reactive flux gas is a recognized method for processing……

The molten aluminum ceramic foam filter plate is composed of an aggregated mesh member made of refractory material and a coating formed on the surface……

In order to manufacture a molten aluminum alloy filter, aggregates such as ceramics are formed into a net shape and baked to obtain an aggregate……